Construction Equipment Manufacturer Financial Model

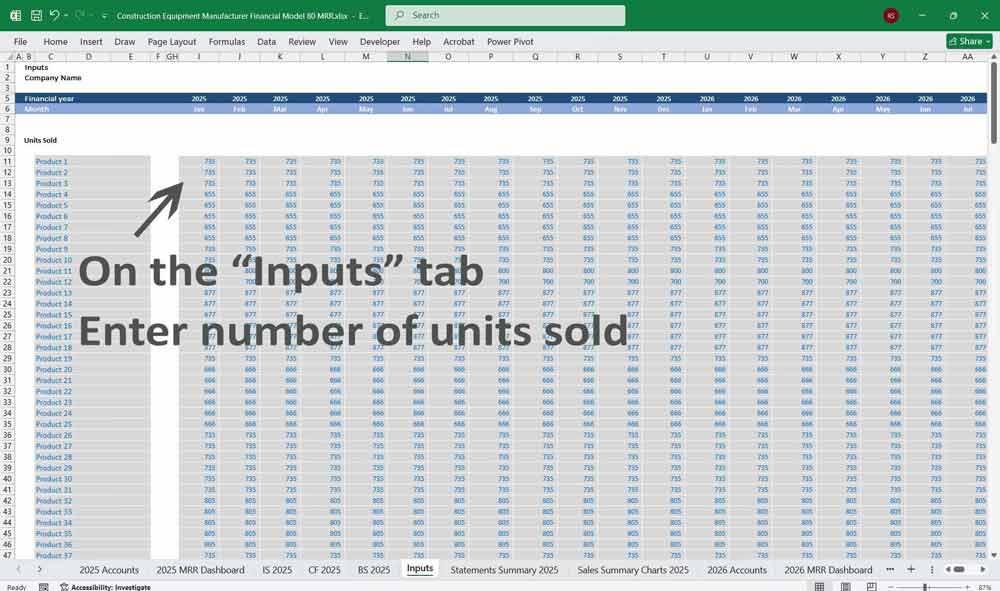

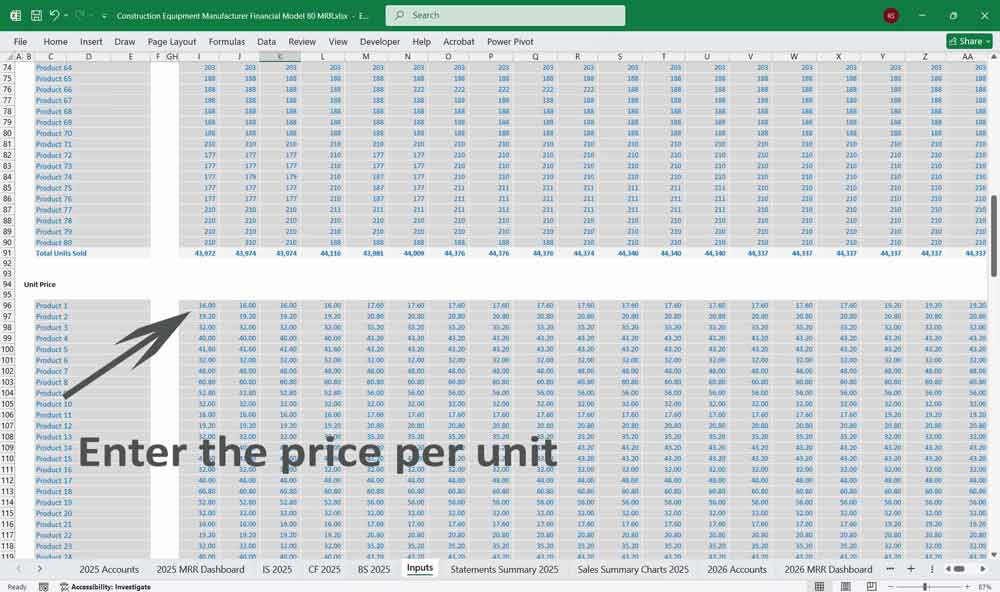

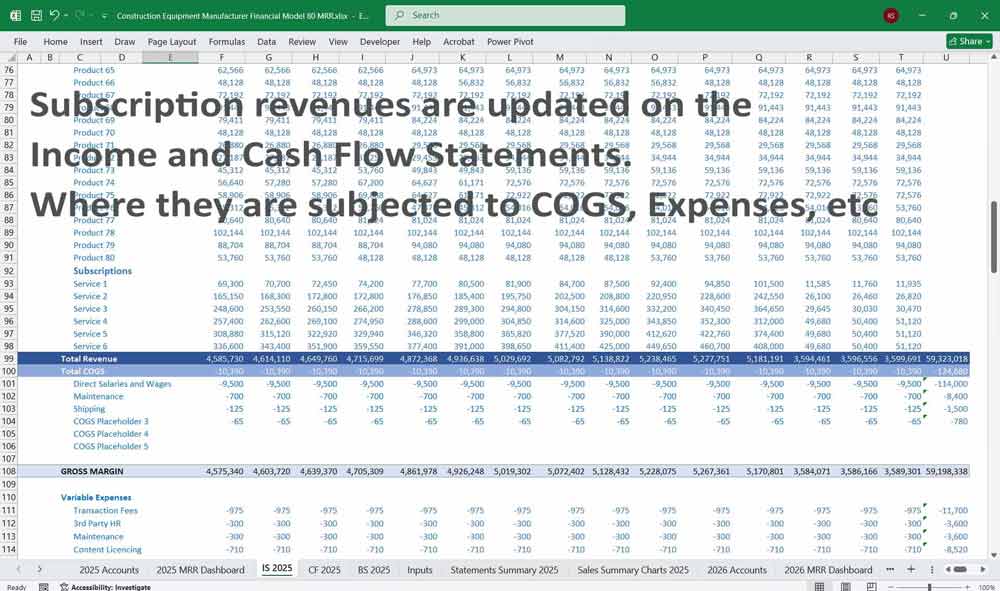

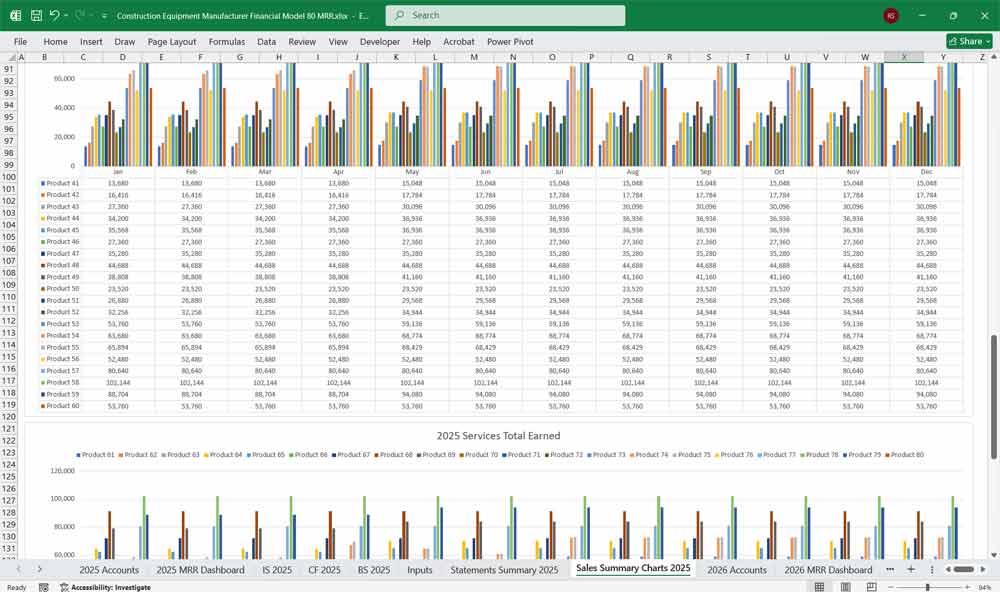

Here’s a comprehensive breakdown of the Excel Financial Models for a Construction Equipment Manufacturer, covering the Income Statement, Cash Flow Statement, and Balance Sheet. With revenues from 80 product lines and a Subscription Add-On. Cost structures and financial model statements to forecast the financial health of your Construction Equipment Manufacturing.

Financial Model for a Construction Equipment Manufacturer

These financial models offer a detailed framework for managing and analyzing the finances of a Construction Equipment Manufacturer. These 20 year models include an Income Statement, Cash Flow Statement, and Balance Sheet to comprehensively understand revenue, expenses, and profitability. Additionally, it incorporates detailed sections for managing an 80-product line portfolio and a 6-Tier Subscription Model Add-on, ensuring scalability, recurring revenue, and customer retention.

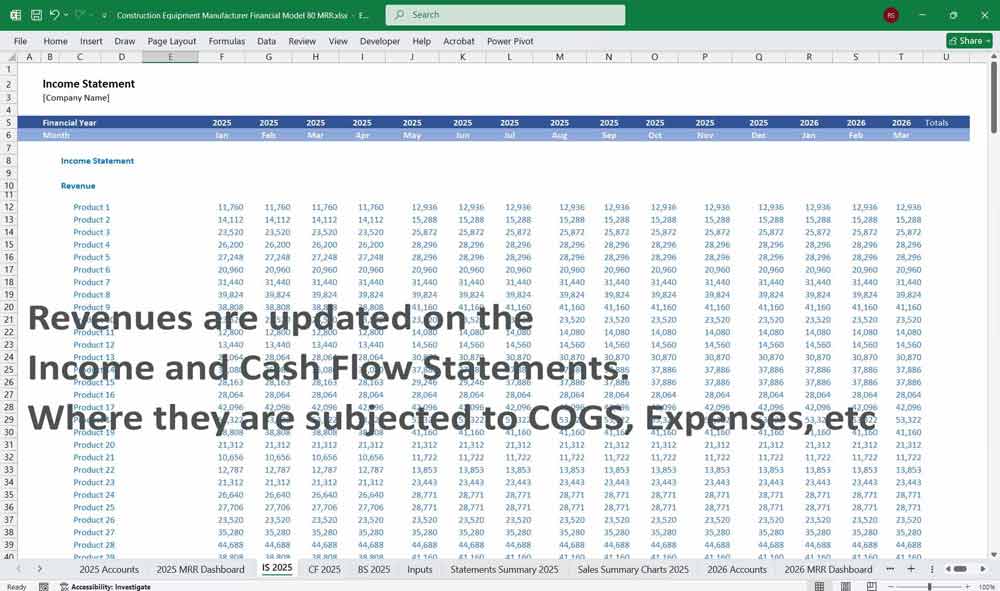

Income Statement

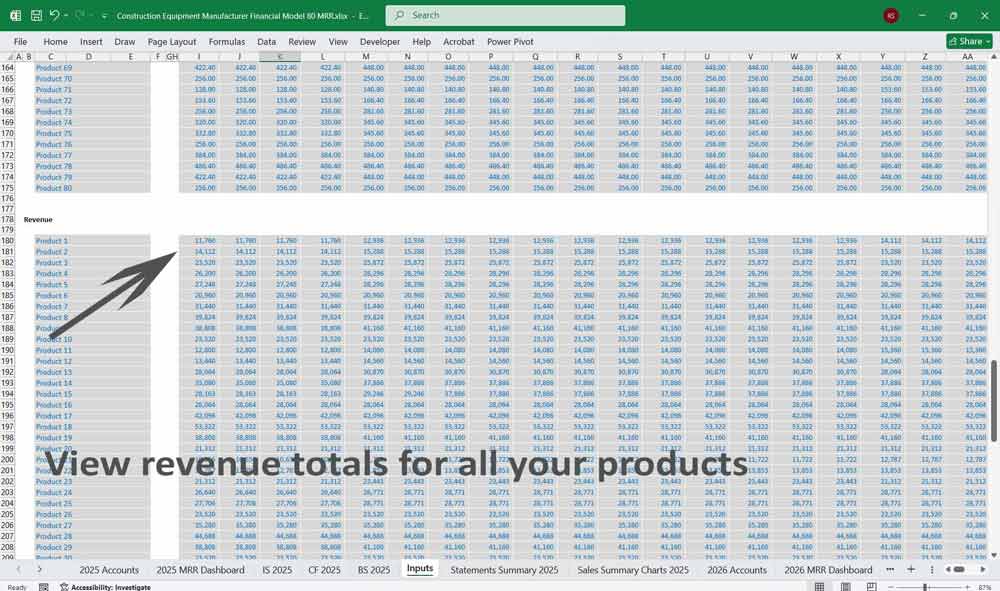

Revenue Streams

- Product Sales:

- Core Equipment: High-demand equipment like excavators, loaders, backhoes, and cranes.

- Specialized Equipment: Niche machinery such as tunneling machines, demolition tools, and pavers.

- Attachments: Buckets, breakers, or other add-ons sold as optional upgrades.

- Rental Services:

- Daily, weekly, or monthly rentals for smaller construction firms.

- Parts and Aftermarket Sales:

- Replacement parts such as hydraulic systems, engine components, and wheels.

- Maintenance kits and consumables.

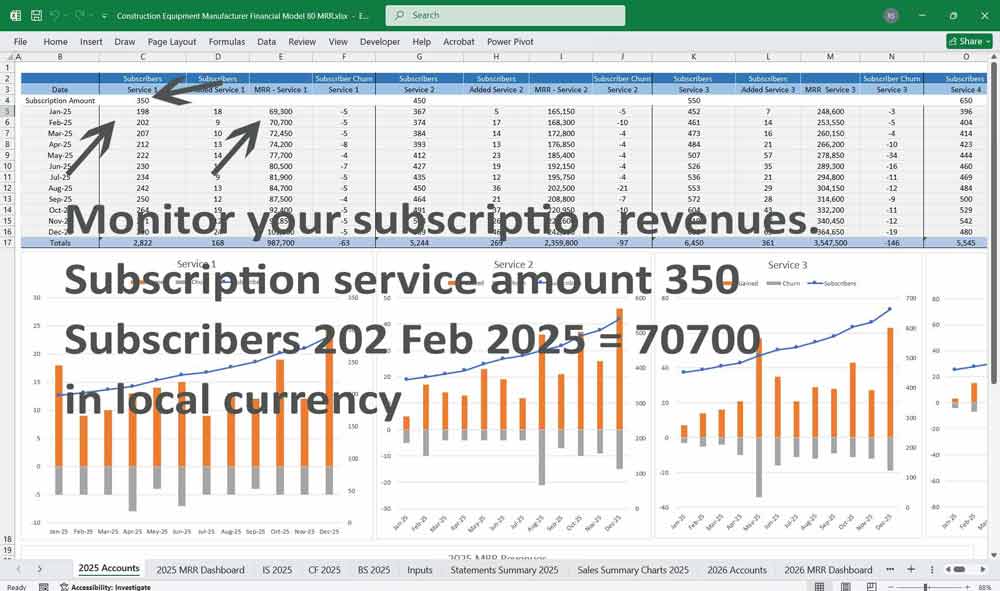

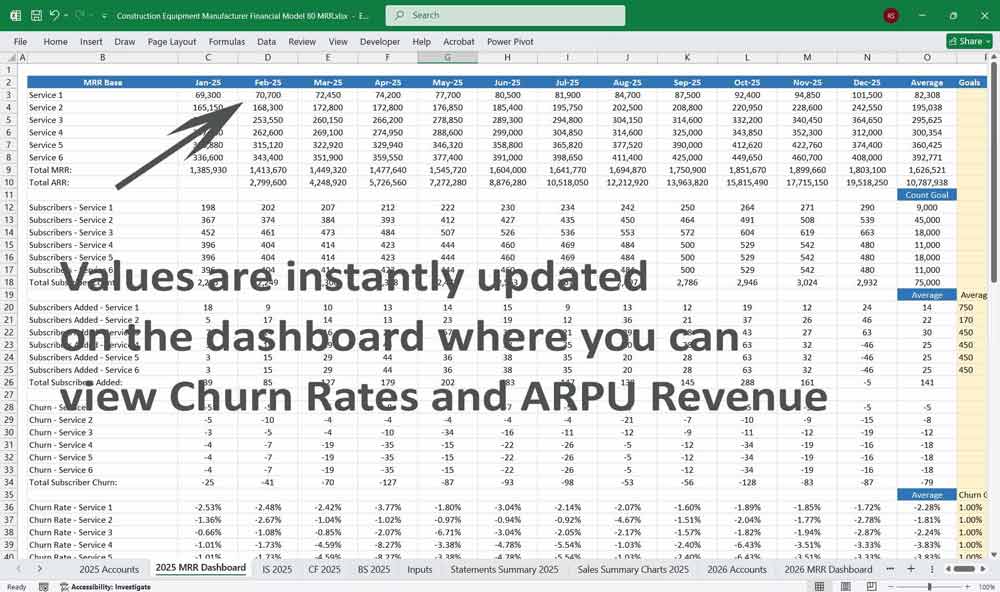

- Subscription Services:

- Predictive maintenance alerts, software upgrades, and equipment performance analytics. (Detailed in Section 5)

- Service Contracts:

- Maintenance agreements, installation services, and operator training programs.

Cost Structure

- Cost of Goods Sold (COGS):

- Materials: High-grade steel, hydraulic parts, engines, and electrical components.

- Labor: Skilled assembly line workers, R&D personnel.

- Overheads: Machinery operations, factory utilities, and equipment calibration.

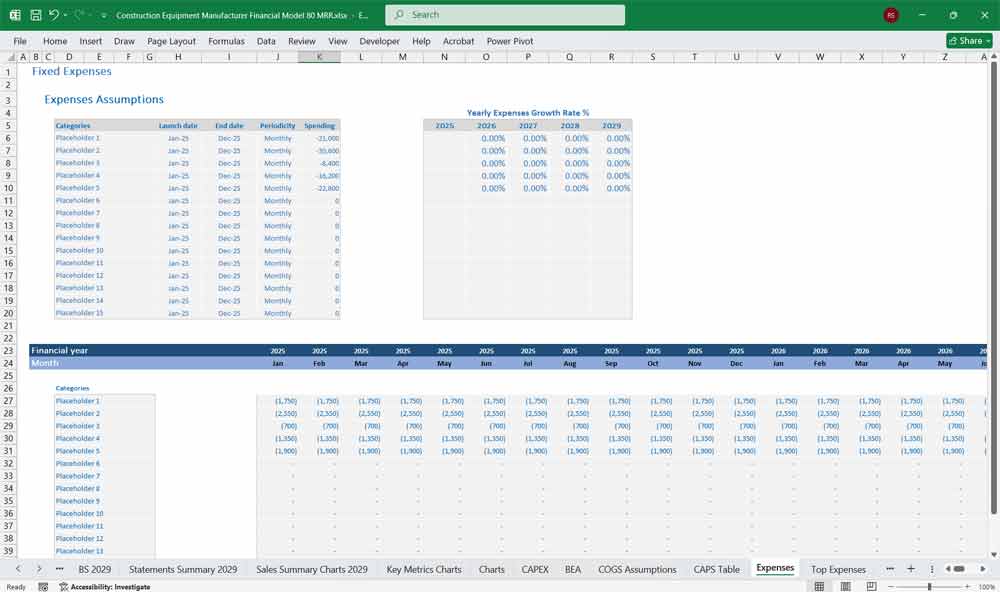

- Operating Expenses:

- R&D: Innovating durable, energy-efficient designs.

- Sales and Marketing: Trade shows, digital marketing, and dealer networks.

- Logistics: Delivering heavy equipment globally.

- Compliance: Certifications like ISO, emissions standards.

- Depreciation:

- Heavy wear and tear on heavy plant machinery depreciation cost allocation.

Profitability Metrics

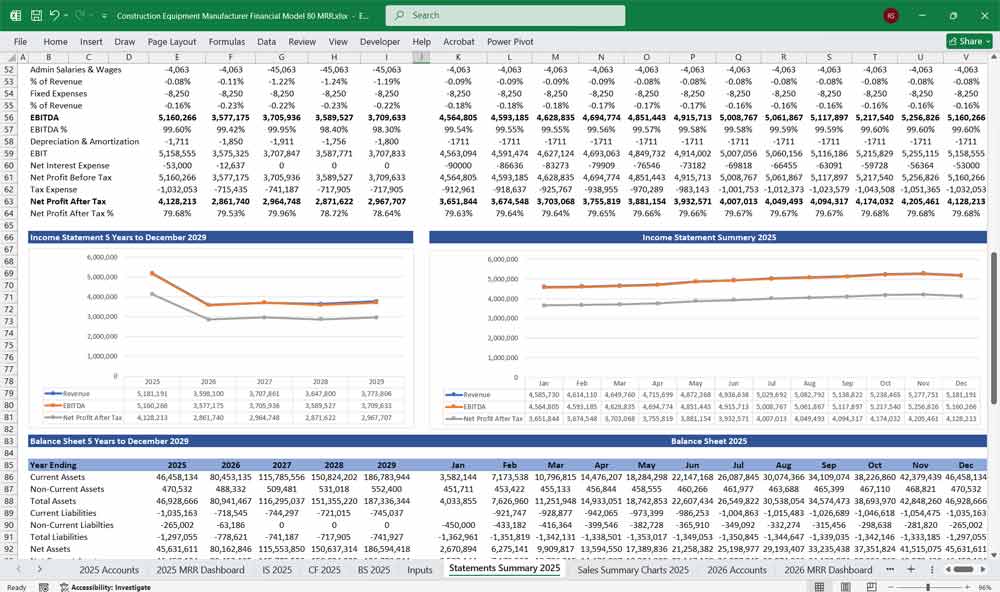

- Gross Profit = Revenue – COGS.

- Operating Profit = Gross Profit – Operating Expenses.

- Net Profit = Operating Profit – Taxes – Interest.

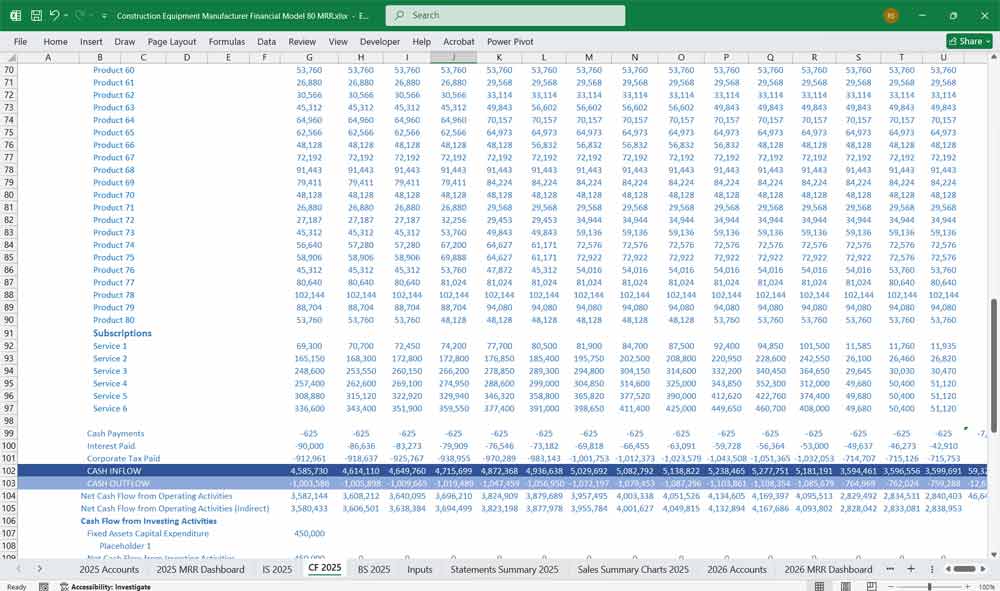

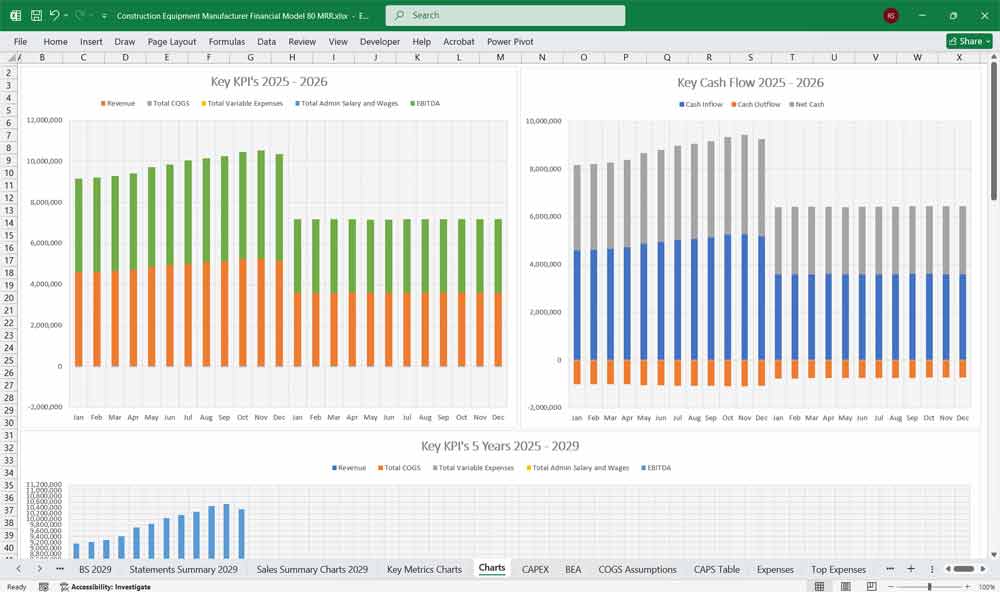

Construction Equipment Manufacturer Financial Model Cash Flow Statement

Operating Activities

- Inflows:

- Payments from equipment sales, rental revenues, and service contracts.

- Subscription model payments.

- Outflows:

- Procurement of raw materials and engine systems.

- Employee wages and factory overhead.

- Marketing and dealer commissions.

Investing Activities

- Inflows:

- Sale of obsolete machinery or unused parts inventory.

- Returns on investments in R&D projects.

- Outflows:

- Facility expansions to accommodate increased production.

- Investments in automation or robotics for precision manufacturing.

Financing Activities

- Inflows:

- Loans for infrastructure expansion or new product development.

- Venture capital or equity financing for scaling.

- Outflows:

- Dividend payments.

- Long-term loan repayments.

Key Metrics

- Free Cash Flow (FCF): Indicates cash available for growth initiatives or distributions.

- Operating Cash Flow (OCF): Monitors core efficiency of day-to-day business operations.

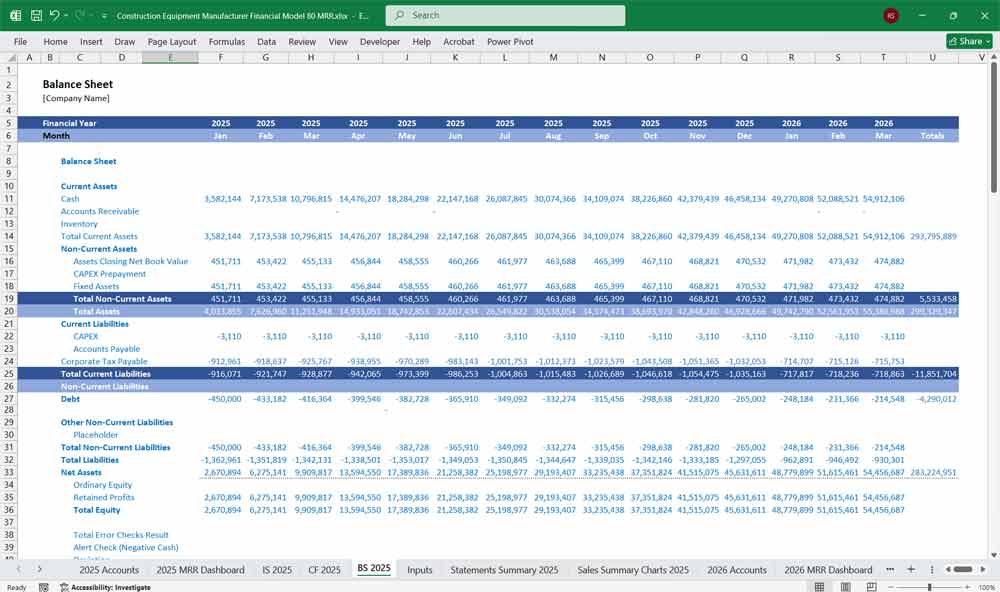

Construction Equipment Manufacturer Financial Model Balance Sheet

Assets

- Current Assets:

- Cash: Available liquidity for short-term needs.

- Accounts Receivable: Outstanding payments from clients and dealers.

- Inventory:

- Raw materials: Steel, electronics, tires.

- Work-in-progress machinery.

- Finished equipment.

- Non-Current Assets:

- Plant and machinery used for production.

- Intellectual property: Patents for unique equipment designs.

- Advanced tools like robotic arms for precision assembly.

Liabilities

- Current Liabilities:

- Supplier payables.

- Accrued expenses for utilities, advertising, and salaries.

- Non-Current Liabilities:

- Long-term loans or bonds issued for new product lines or factory expansions.

Equity

- Retained earnings for reinvestment.

- Capital contributed by shareholders for scaling operations.

Key Financial Metrics for a Construction Equipment Manufacturer

- Gross Profit Margin = (Gross Profit / Revenue) × 100

- Operating Profit Margin (EBIT Margin) = (EBIT / Revenue) × 100

- Net Profit Margin = (Net Income / Revenue) × 100

- Return on Assets (ROA) = (Net Income / Total Assets) × 100

- Return on Equity (ROE) = (Net Income / Shareholder Equity) × 100

- Debt-to-Equity Ratio = (Total Debt / Shareholder Equity)

- Inventory Turnover = (COGS / Average Inventory)

- Days Sales Outstanding (DSO) = (Accounts Receivable / Revenue) × 365

When structuring product lines for construction equipment manufacturing that may be used in the construction plant hire business, it’s important to organize them in a way that aligns with customer needs, market demand, and operational efficiency. Below are detailed sections for 40 product lines and 80 product lines, including categorization, examples, and strategic considerations.

80 Product Line Breakdown

Below is an estimated list for basic 80 product lines

1. Construction Earthmoving Equipment

Construction Excavators

Mini Excavators

Crawler Excavators

Wheeled Excavators

Long-Reach Construction Excavators

Construction Bulldozers

Crawler Dozers

Wheeled Dozers

Loaders for Construction

Skid Steer Loaders

Backhoe Loaders

Wheeled Loaders

Track Loaders

Graders for Construction

Motor Graders

Compact Graders

2. Material Handling Construction Equipment

Construction Cranes

Mobile Cranes

Tower Cranes

Crawler Cranes

Construction Forklifts

Rough Terrain Forklifts

Industrial Forklifts

Construction Conveyors

Belt Conveyors

Screw Conveyors

Construction Hoists

Electric Hoists

Manual Hoists

3. Road Construction Equipment

Asphalt Construction Pavers

Tracked Pavers

Wheeled Pavers

Construction Rollers

Single Drum Rollers

Double Drum Rollers

Pneumatic Rollers

Construction Cold Planers

Small Planers

Large Planers

Construction Road Marking Machines

Hand-Operated Markers

Truck-Mounted Markers

4. Concrete Equipment

Construction Concrete Mixers

Drum Mixers

Twin-Shaft Mixers

Construction Concrete Pumps

Stationary Pumps

Truck-Mounted Pumps

Construction Batching Plants

Mobile Batching Plants

Stationary Batching Plants

Construction Vibrators

Internal Vibrators

External Vibrators

5. Mining Equipment

Construction Drilling Rigs

Surface Drilling Rigs

Underground Drilling Rigs

Construction Haul Trucks

Articulated Dump Trucks

Rigid Dump Trucks

Load-Haul-Dump (LHD) Construction Loaders

Electric LHDs

Diesel LHDs

Shovels for Heavy Construction

Hydraulic Shovels

Electric Rope Shovels

6. Utility Equipment

Trenchers for Construction

Chain Trenchers

Wheel Trenchers

Construction Compactors

Plate Compactors

Vibratory Rollers

Construction Generators

Diesel Generators

Portable Generators

Light Tower for Construction Sites

Towable Light Towers

Solar-Powered Light Towers

7. Attachments & Accessories

Heavy Construction Buckets

Excavator Buckets

Loader Buckets

Hydraulic Construction Breakers

Small Breakers

Large Breakers

Construction Grapples

Log Grapples

Scrap Grapples

28 Augers Equipment

Earth Augers

Rock Augers

8. Specialty Equipment

Tunnel Boring Construction Machines (TBMs)

Hard Rock TBMs

Soft Ground TBMs

Pile Driver Equipment

Diesel Pile Drivers

Hydraulic Pile Drivers

Dredging Euipment

Cutter Suction Dredgers

Bucket Dredgers

Demolition Equipment

High-Reach Excavators

Hydraulic Crushers

9. Support Equipment

Construction Site Fuel Trucks

Mobile Fuel Trucks

Stationary Fuel Tanks

Construction Water Trucks

Sprinkler Trucks

Tanker Trucks

Equipment Service Vehicles

Maintenance Trucks

Inspection Vehicles

Equipment Trailers

Flatbed Trailers

Lowboy Trailers

10. Technology & Automation

Construction GPS & Telematics Systems

Fleet Management Systems

Machine Control Systems

Construction Site Drones

Surveying Drones

Inspection Drones

Autonomous Equipment

Self-Driving Loaders

Autonomous Haul Trucks

Wearable Tech Equipment

Smart Helmets

Safety Vests with Sensors

80 Product Lines for a Construction Equipment Manufacturer

This example of expanded 80 product lines shows a probable expansion on the 80 above, adding more specialised and niche equipment.

11. Aerial Work Platforms

Scissor Lift Equipment

Electric Scissor Lifts

Rough-Terrain Scissor Lifts

Boom Lift Equipment

Articulating Boom Lifts

Telescopic Boom Lifts

Vertical Mast Lift Equipment

Indoor Mast Lifts

Outdoor Mast Lifts

Spider Lift Equipment

Compact Spider Lifts

Heavy-Duty Spider Lifts

12. Compaction Equipment

Construction Vibratory Plates

Reversible Plates

Forward Plates

Construction Rammers

Single-Speed Rammers

Variable-Speed Rammers

Construction Site Trench Rollers

Ride-On Trench Rollers

Walk-Behind Trench Rollers

Landfill Compactor Equipment

High-Density Compactors

Low-Density Compactors

13. Pumps & Dewatering Equipment

Construction Site Submersible Pumps

Light-Duty Pumps

Heavy-Duty Pumps

Trash Pump Equipment

Portable Trash Pumps

Stationary Trash Pumps

Dewatering Pump Equipment

Electric Dewatering Pumps

Diesel Dewatering Pumps

Slurry Pump Equipment

Centrifugal Slurry Pumps

Positive Displacement Pumps

14. Environmental Equipment

Recycling Machine Equipment

Concrete Recyclers

Asphalt Recyclers

Dust Suppression System Equipment

Water-Based Systems

Chemical-Based Systems

Construction Site Noise Barriers

Portable Noise Barriers

Permanent Noise Barriers

Erosion Control Equipment

Silt Fences

Hydroseeding Machines

15. Forestry Equipment

57 .

Harvesters

Wheeled Harvesters

Tracked Harvesters

Forwarder Equipment

Short-Log Forwarders

Long-Log Forwarders

Mulcher Equipment

Skid Steer Mulchers

Excavator Mulchers

Chipper Equipment

Drum Chippers

Disc Chippers

16. Pipeline Equipment

Pipe Layer equipment

Crawler Pipe Layers

Wheeled Pipe Layers

Pipe Bender Equipment

Hydraulic Pipe Benders

Manual Pipe Benders

Coating Machine equipment

Pipe Coating Machines

Joint Coating Machines

Construction Inspection Crawlers

Pipeline Crawlers

CCTV Crawlers

17. Marine Equipment

Construction Site Floating Cranes

Small Floating Cranes

Heavy-Lift Floating Cranes

Equipment Barges

Dump Barges

Spud Barges

Construction Site Amphibious Excavators

Marsh Bugies

Swamp Dozers

Diving Equipment

Surface-Supplied Diving Systems

Saturation Diving Systems

18. Agricultural Equipment

Construction Site Tractors

Utility Tractors

Row-Crop Tractors

Construction Site Plows

Moldboard Plows

Disc Plows

Harvester Equipment

Combine Harvesters

Forage Harvesters

Construction Site Sprayers

Boom Sprayers

Airblast Sprayers

19. Energy Equipment

Solar Installation Equipment

Ground-Mount Installers

Roof-Mount Installers

Wind Turbine Crane Equipment

Onshore Cranes

Offshore Cranes

Geothermal Drill Equipment

Rotary Drills

Percussion Drills

Battery-Powered Equipment

Electric Excavators

Electric Loaders

20. Miscellaneous Equipment

Construction Site Portable Toilets

Standard Units

Deluxe Units

Construction Site Traffic Control Equipment

Barricades

Traffic Cones

Heating Equipment

Portable Heaters

Radiant Heaters

Blasting Equipment

Explosive Loaders

Blasting Mats

This comprehensive idea list covers a wide range of construction equipment, from heavy machinery to specialized tools and accessories. Each product line can be further customized on your model based on market demand, technological advancements, and your customer requirements.

6-Tier Subscription Model

Designed to create a recurring revenue stream and boost customer engagement.

Tier Structure

Tier 1 (Basic Construction Equipment Service):

- Notifications for service intervals.

- Pricing: Low-cost, fixed monthly fee with no customization.

- Discounts: 5% discount on additional orders beyond the subscription volume.

Tier 2 (Standard

Construction Equipment

Analytics):

- Usage analytics for operational optimization.

- Delivery: Priority delivery (3-5 business days).

- Support: Dedicated manager and phone support.

Tier 3 (Professional

Construction Equipment

Diagnostics):

- Advanced diagnostics and troubleshooting reports.

- Delivery: Expedited delivery (1-3 business days).

- Support: 24/7 dedicated support and technical assistance.

Tier 4 (Enhanced

Construction Equipment

Performance):

- AI-powered recommendations to extend machinery lifespan.

- Quarterly health checks.

- Delivery: Guaranteed next-day delivery.

- Support: On-site technical support and consulting services.

Tier 5 (Enterprise

Construction Equipment

Management):

- Fleet management system for large companies.

- Customized training modules.

- Pricing: Premium pricing with a 10% discount for long-term commitments.

- Support: Sustainability consulting and reporting.

Tier 6 (Custom

Construction Equipment):

- On-site technical support.

- Custom predictive analytics for megaprojects.

- Delivery: Flexible delivery options (standard, priority, or expedited).

- Pricing: Reduced Pay-as-you-go pricing with no additional fees.

Additional Considerations Across Tiers

Scalability:

Each tier is designed to be scalable, allowing customers to upgrade as their production needs grow.Integration & API Access:

Higher tiers offer greater levels of system integration, enabling seamless connectivity with in-house systems and real-time tracking.Flexibility:

Options for rollover of unused print credits and flexible overage billing ensure that customers only pay for what they need.Value-Added Services:

Complimentary design consultations, technical support, and training workshops become more prominent in the higher tiers, adding strategic value beyond just production capacity.Service Level Agreements (SLAs):

Defined SLAs across tiers provide transparency regarding turnaround times, quality standards, and uptime guarantees, with the most rigorous SLAs reserved for Enterprise and Premium tiers.

Final Notes on the Financial Model

Financial model for a Construction Equipment manufacturer

- Scenario Analysis: Create best-case, base-case, and worst-case projections.

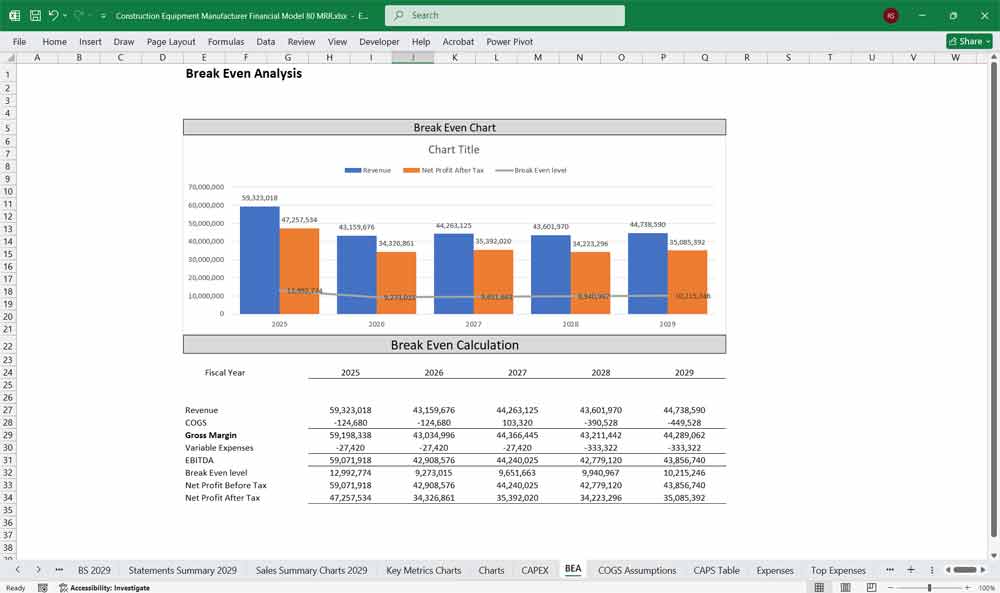

- Break-even Analysis: Determine sales volume required to cover fixed & variable costs.

- Sensitivity Analysis: Assess how changes in raw material costs, pricing, or demand impact profitability.

This structured model bundle helps any Construction Equipment manufacturing company address a broad market spectrum, offering the right balance between cost, production capacity, and support.

Download Link On Next Page