CNC Components Manufacturer Financial Model

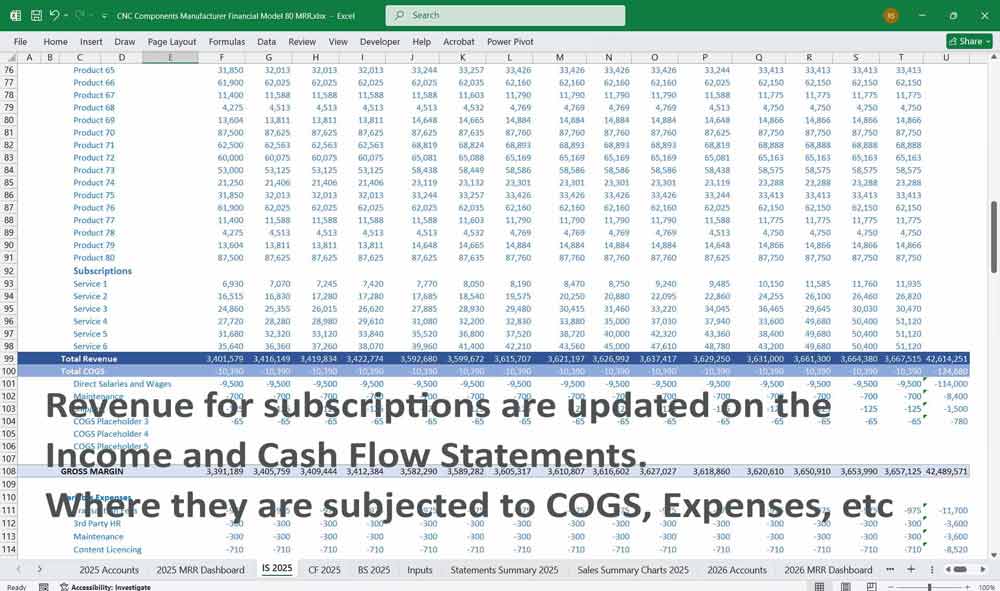

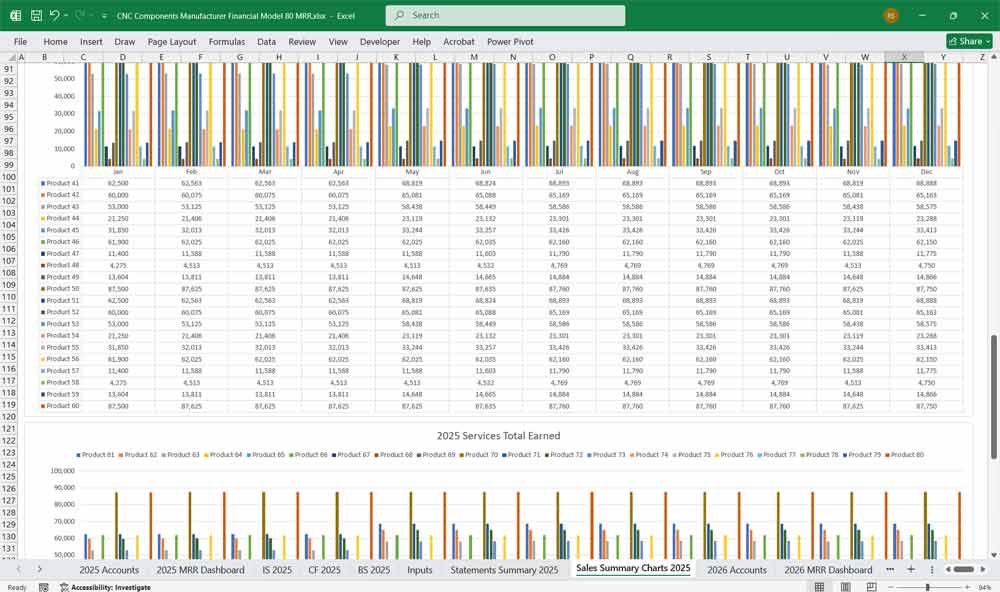

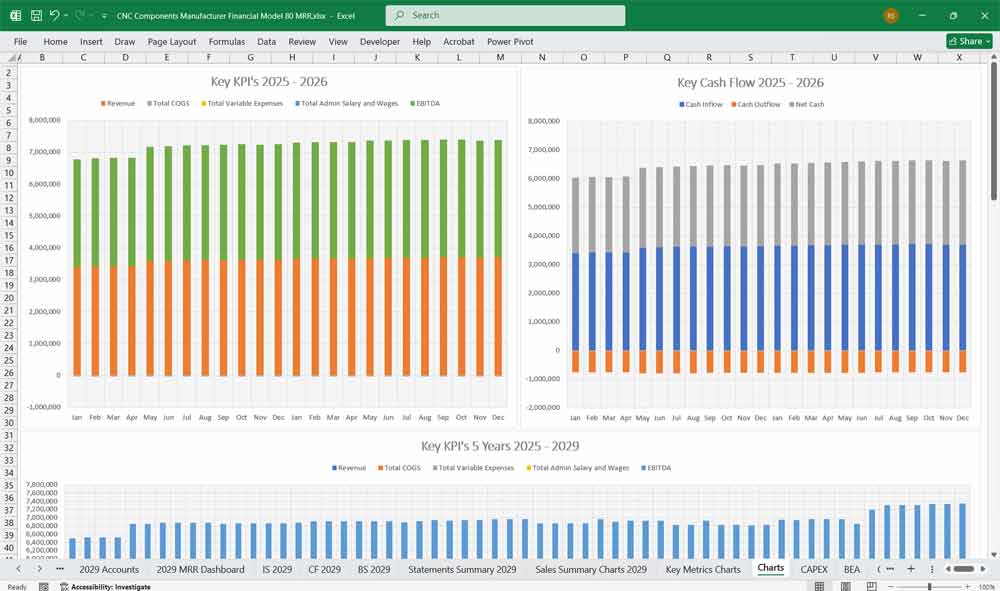

Here’s a comprehensive breakdown of the Excel Financial Models for a CNC Components Manufacturer, covering the Income Statement, Cash Flow Statement, and Balance Sheet. With revenues from up to 80 product lines and a Subscription Add-On. Cost structures and financial statements to forecast the financial health of your CNC Manufacturing. For the best 3D Printing model, go here.

Financial Model for a CNC Components Manufacturer

Covering key components such as the Income Statement, Cash Flow Statement, and Balance Sheet.

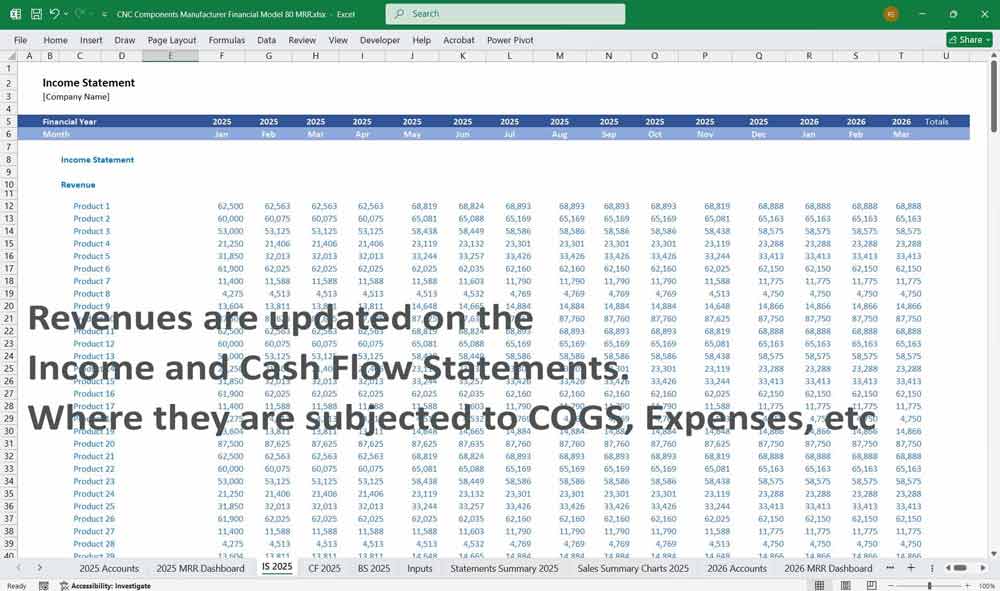

Income Statement (Profit & Loss Statement)

The Income Statement projects the revenue, expenses, and profitability of the CNC manufacturing business over a specific period.

A. Revenue

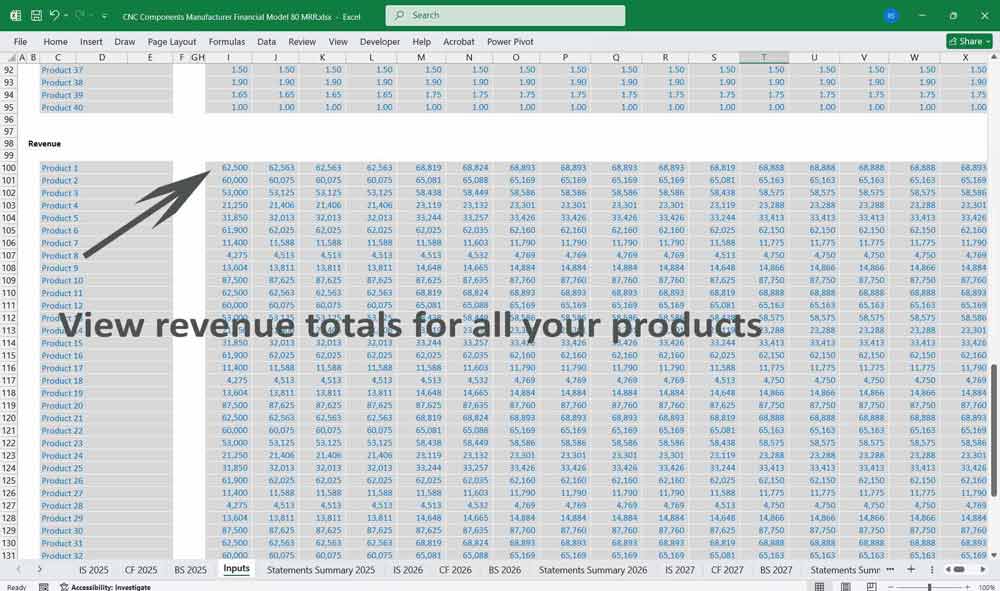

Product Sales Revenue:

- Revenue from CNC-machined components sold to customers.

- Can be broken down by product type (e.g., aerospace parts, automotive parts, medical device components).

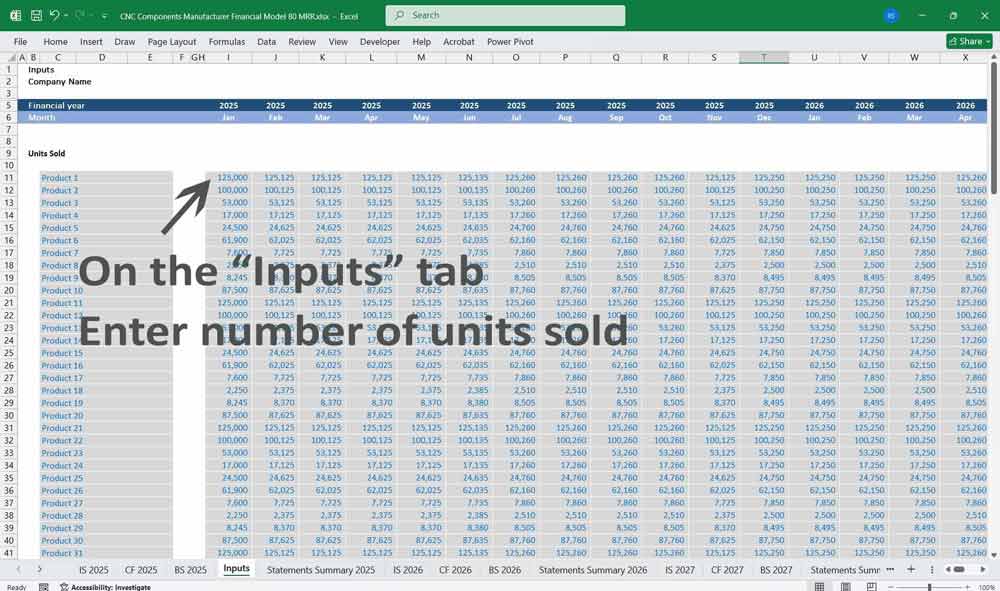

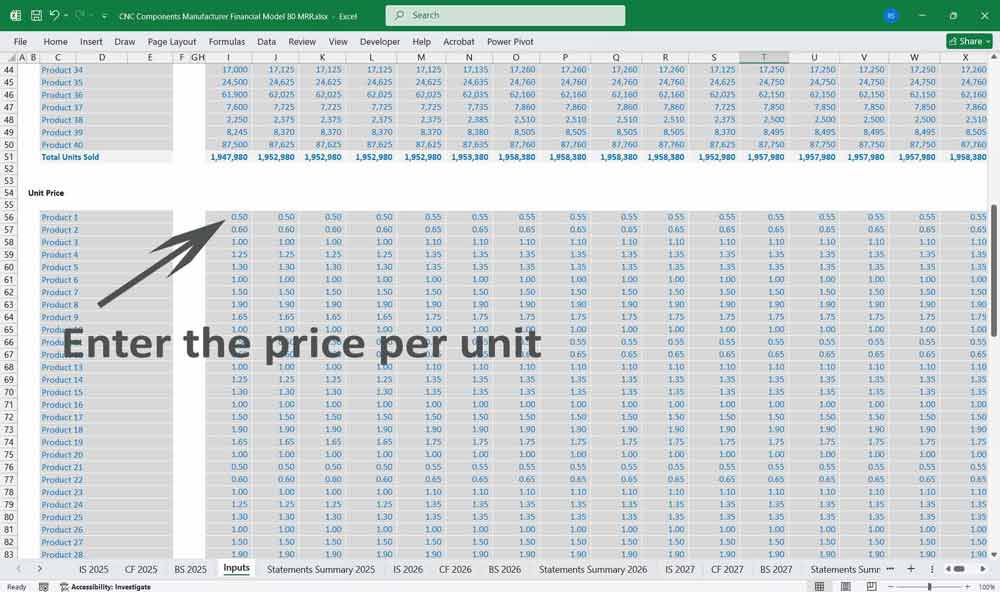

- Revenue = Number of Units Sold × Price per Unit.

Custom Machining Services Revenue:

- Revenue from specialized CNC machining services.

- Charged per hour or per project.

Other Revenue Streams:

- Scrap metal sales.

- Consulting or design services.

- Maintenance and repair services.

B. Cost of Goods Sold (COGS)

Raw Materials Costs:

- Metals, plastics, and other materials used in production.

Direct Labor Costs:

- Wages of machine operators and production staff.

Machine Operating Costs:

- Electricity, coolant, tooling, and maintenance.

Depreciation on CNC Machines:

- Straight-line or declining balance method depreciation.

Manufacturing Overhead:

- Factory rent, utilities, and indirect labor.

C. Gross Profit

- Gross Profit = Revenue – COGS

- Measures production efficiency and profitability.

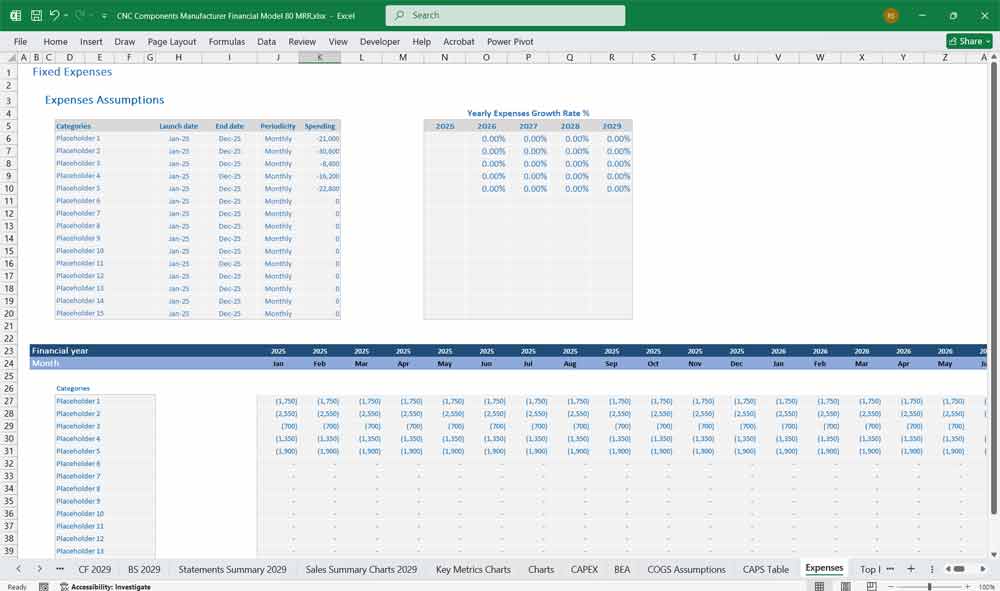

D. Operating Expenses (OPEX)

Selling, General & Administrative (SG&A) Expenses:

- Sales and marketing expenses.

- Office rent, salaries for administrative staff, legal and accounting fees.

Research & Development (R&D):

- New product development, process improvements.

Insurance Costs:

- Equipment, liability, and employee insurance.

Interest Expense on Loans:

- If the company has financing for machinery or operations.

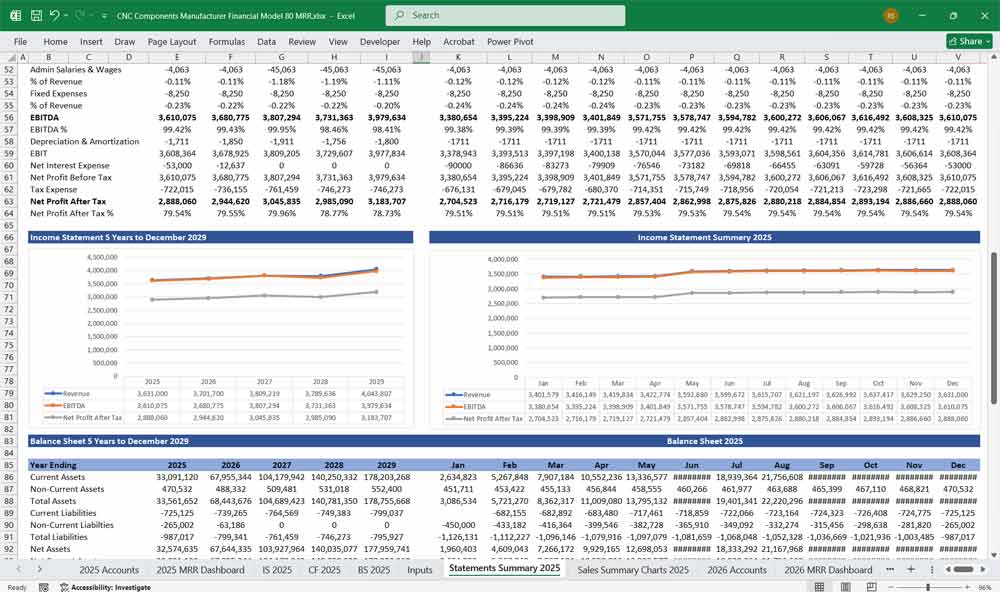

E. EBITDA (Earnings Before Interest, Taxes, Depreciation, and Amortization)

- EBITDA = Gross Profit – Operating Expenses

- Shows profitability before non-operating costs.

F. Depreciation & Amortization

- Depreciation of CNC machinery and amortization of intangible assets.

G. EBIT (Operating Profit)

- EBIT = EBITDA – Depreciation & Amortization

H. Net Income

- Net Income = EBIT – Interest – Taxes

- Final profitability figure after all expenses.

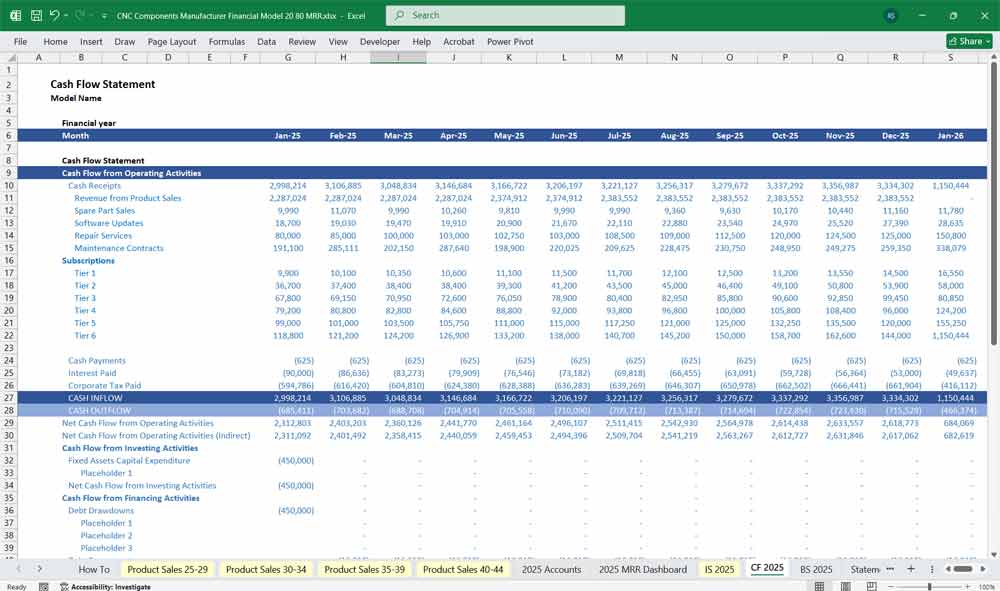

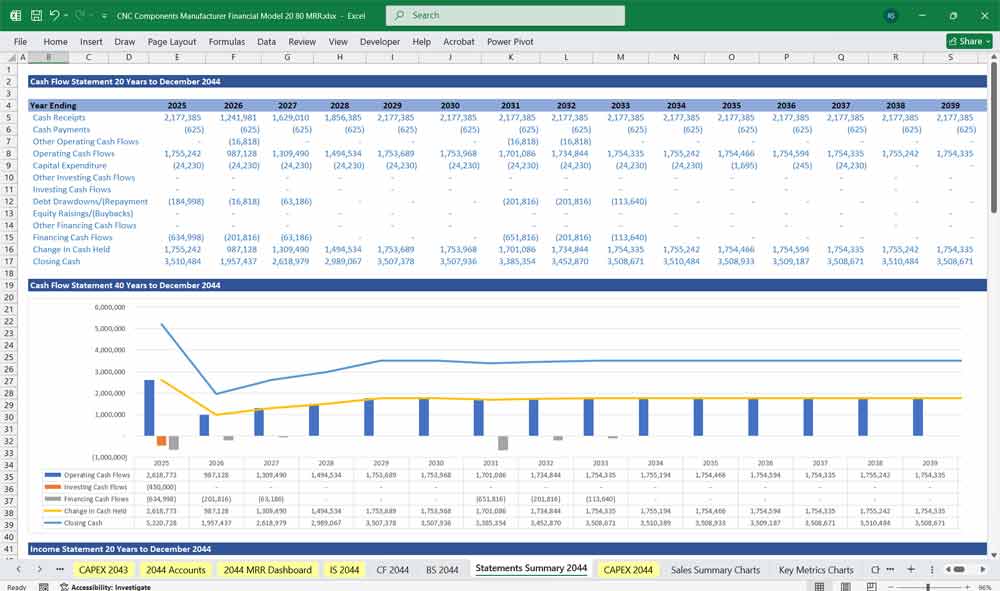

CNC Components Manufacturer Cash Flow Statement

The Cash Flow Statement tracks cash movement to ensure the business has enough liquidity.

A. Cash Flow from Operating Activities (CFO)

Cash Inflows:

- Revenue from sales.

- Advance payments from customers.

Cash Outflows:

- Raw component material purchases.

- Wages and salaries.

- Rent and utilities.

- Taxes paid.

Adjustments for Non-Cash Items:

- Depreciation and amortization are added back.

- Changes in accounts receivable and accounts payable.

B. Cash Flow from Investing Activities (CFI)

Capital Expenditures (CAPEX):

- Purchases of CNC machines, equipment, and facility upgrades.

Asset Sales:

- Selling old or unused machinery.

Investments:

- If the company invests in new business ventures.

C. Cash Flow from Financing Activities (CFF)

Cash Inflows:

- Bank loans, investor funding, or equipment financing.

- Issuance of equity or debt.

Cash Outflows:

- Loan repayments.

- Dividend payments to shareholders.

D. Net Cash Flow & Ending Cash Balance

- Net Cash Flow = CFO + CFI + CFF

- Final cash balance at the end of the period.

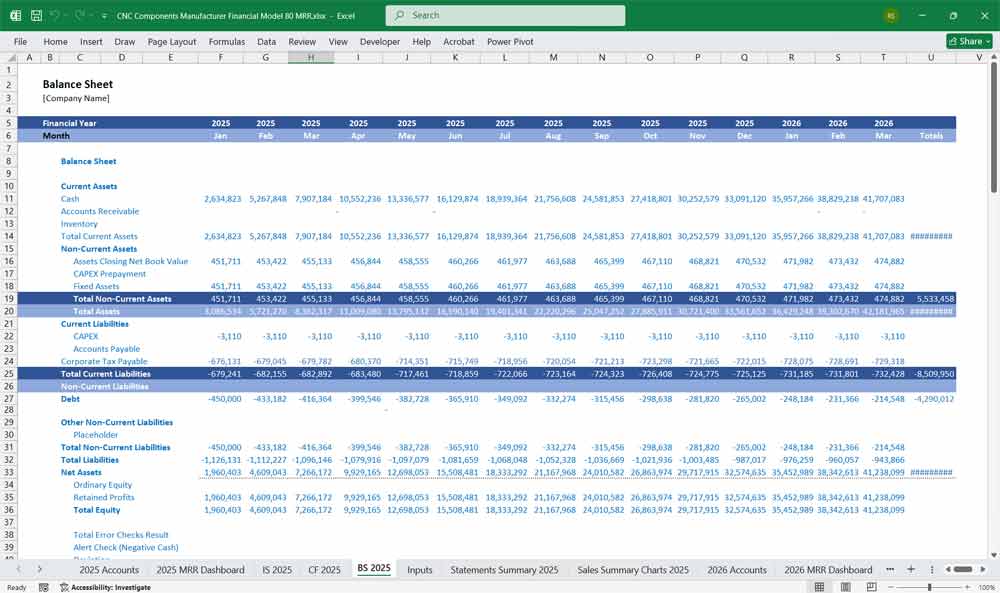

CNC Components Manufacturer Balance Sheet

The Balance Sheet provides a snapshot of the company’s financial position at a given point.

A. Assets

Current Assets:

- Cash & Cash Equivalents: Money in the bank.

- Accounts Receivable: Outstanding customer invoices.

- Inventory: Raw materials, work-in-progress, finished goods.

- Prepaid Expenses: Rent, insurance, and other prepaid costs.

Non-Current Assets:

- Property, Plant, and Equipment (PP&E): CNC machines, factory building, office equipment.

- Intangible Assets: Patents, trademarks, goodwill (if applicable).

B. Liabilities

Current Liabilities:

- Accounts Payable: Unpaid supplier invoices.

- Short-Term Loans & Lease Obligations: Loan payments due within a year.

- Taxes Payable: Unpaid tax obligations.

- Accrued Expenses: Unpaid wages, utilities, or other costs.

Non-Current Liabilities:

- Long-Term Debt: Loans for machinery or factory expansion.

- Deferred Tax Liabilities: Future tax obligations.

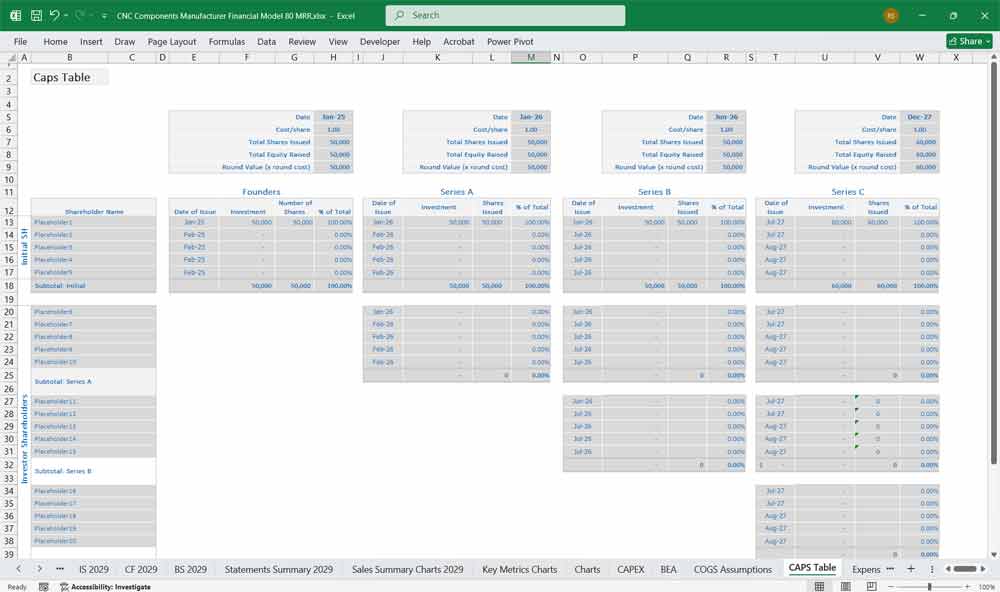

C. Equity

Owner’s Equity / Retained Earnings:

- Profits reinvested in the business.

Shareholder’s Equity (if applicable):

- If there are external investors or partners.

Total Assets = Total Liabilities + Equity

- Ensures the balance sheet equation holds.

Key Financial Metrics for an CNC Components Manufacturer

- Gross Profit Margin = (Gross Profit / Revenue) × 100

- Operating Profit Margin (EBIT Margin) = (EBIT / Revenue) × 100

- Net Profit Margin = (Net Income / Revenue) × 100

- Return on Assets (ROA) = (Net Income / Total Assets) × 100

- Return on Equity (ROE) = (Net Income / Shareholder Equity) × 100

- Debt-to-Equity Ratio = (Total Debt / Shareholder Equity)

- Inventory Turnover = (COGS / Average Inventory)

- Days Sales Outstanding (DSO) = (Accounts Receivable / Revenue) × 365

When structuring product lines for a CNC components manufacturer, it’s important to organize them in a way that aligns with customer needs, market demand, and operational efficiency. Below are detailed sections for up to 80 product lines, including categorization, examples, and strategic considerations.

Product Lines Example Structure:

(Organized into 5 major categories, each with subcategories)

1. Precision Machined CNC Components (8)

- CNC Turned Parts

- CNC Milled Parts

- Multi-Axis Machined Components

- Micro Machined Parts

- High-Precision Shafts

- Custom Machined Brackets

- Surface-Treated Machined Parts

- Hardened and Ground Components

2. Automotive CNC Components (8)

- Engine Mounting Brackets

- Transmission Housings

- CNC Machined Pistons

- Turbocharger Components

- Fuel Injection System Parts

- Axle and Suspension Components

- Precision Bushings

- Steering System Components

3. Aerospace & Defense CNC Components (8)

- Aircraft Structural Components

- High-Precision Aerospace Bushings

- Landing Gear CNC Parts

- Missile Guidance System Parts

- Radar System Components

- Satellite Communication Housings

- Jet Engine Components

- Lightweight Aluminum Aerospace Parts

4. Medical & Healthcare CNC Components (8)

- Surgical Instrument Components

- Titanium Implants & Prosthetics

- Dental CNC Parts

- Diagnostic Equipment Parts

- Micro Machined Bone Screws

- Blood Pump Components

- Endoscopic Equipment CNC Parts

- MRI & CT Scanner Components

5. Industrial & Electronics CNC Parts (8)

- Custom Heat Sinks

- RF & Microwave CNC Components

- Semiconductor Equipment Parts

- Custom Metal Enclosures

- CNC Machined Fasteners

- CNC Precision Gears

- Optical Instrument Parts

- Custom Jigs & Fixtures

Strategic Considerations:

Market Focus: Prioritize high-demand categories like industrial and specialty chemicals.

Operational Efficiency: Limit the number of SKUs per product line to reduce complexity.

Customer Segmentation: Tailor offerings to regional or niche markets (e.g., agrochemicals for agricultural regions).

Sustainability: Include eco-friendly or green chemical options to meet regulatory and customer demands.

80 Product Lines Structure:

(A broader categorization with more detailed subcategories)

1. Precision CNC Machining (10)

- CNC Turning & Milling Parts

- 5-Axis Machined Components

- Hardened & Ground Shafts

- Optical Instrument Components

- Micro CNC Machined Parts

- Surface-Coated CNC Parts

- Welded & Machined Assemblies

- CNC Titanium Parts

- Custom Aluminum Extrusions

- Machined Stainless Steel Components

2. Automotive CNC Components (10)

- Engine Cylinder Heads

- CNC Machined Connecting Rods

- Turbocharger Housing & Impellers

- CNC Gearbox Components

- Steering Column Parts

- High-Strength Aluminum Auto Parts

- Exhaust Manifold Components

- Custom Machined Axles

- CNC Machined Brake Calipers

- Differential Housing Components

3. Aerospace & Defense CNC Components (10)

- CNC Aircraft Fasteners

- Landing Gear Struts

- Aerospace Hydraulic Components

- Titanium Jet Engine Parts

- Radar System CNC Mounts

- Aerospace Bearing Housings

- Missile & UAV Precision Parts

- CNC Machined Drone Frames

- Composite Material Machined Parts

- Lightweight Structural Aerospace Parts

4. Medical & Healthcare CNC Components (10)

- CNC Machined Bone Screws

- Titanium Surgical Instruments

- Dental Implant CNC Parts

- Robotic Surgery Arm Components

- CNC Machined Prosthetic Joints

- Stainless Steel Medical Brackets

- Custom MRI Scanner Parts

- Endoscopy Equipment Machined Parts

- Micro-Machined Catheter Components

- Orthopedic Implant Components

5. Industrial & General CNC Engineering (10)

- CNC Machined Tooling Fixtures

- Custom CNC Gear Blanks

- Large Industrial Shafts

- Pump & Valve CNC Components

- High-Temperature Alloy Machined Parts

- CNC Mold and Die Components

- Precision Machine Bases

- High-Speed Spindle Shafts

- Industrial Pneumatic Components

- CNC Laser Cut Parts

6. Electronics & Semiconductor CNC Parts (10)

- CNC Machined RF Connectors

- CNC Precision Aluminum Heat Sinks

- Semiconductor Processing Equipment Parts

- CNC Machined Instrument Panels

- High-Tolerance Copper Components

- CNC Machined Sensor Enclosures

- Precision RF Waveguide Components

- Aluminum Brackets for Circuit Boards

- CNC Machined High-Frequency Antenna Parts

- Custom EMI Shielding Components

7. Oil & Gas CNC Components (10)

- High-Pressure Valve Components

- CNC Machined Drill Bits

- Offshore Platform Precision Parts

- Custom CNC Machined Pipe Fittings

- Hydraulic Pump CNC Components

- CNC Machined Downhole Tool Parts

- Large Diameter CNC Flanges

- Heat-Resistant CNC Alloy Components

- Subsea Equipment CNC Parts

- Precision Machined Ball Valves

8. CNC and Renewable Energy & Power Generation (10)

- Wind Turbine Precision Components

- CNC Machined Hydro Turbine Parts

- Solar Panel Frame CNC Machining

- High-Efficiency Generator Components

- CNC Machined Electric Motor Casings

- Battery Housing & Enclosures

- CNC Machined Power Grid Components

- Geothermal Energy Equipment Parts

- CNC Machined Transformer Components

- Large-Scale Custom CNC Energy Parts

Strategic Considerations:

Global Reach: Ensure product lines meet international regulatory standards (e.g., REACH, FDA).

Customization: Offer tailored formulations for key clients in industries like automotive, electronics, and healthcare.

Innovation: Invest in R&D to develop cutting-edge products (e.g., bio-based chemicals, nanotechnology).

Sustainability: Expand eco-friendly and circular economy-focused product lines.

Supply Chain Optimization: Implement advanced inventory and logistics systems to manage the increased complexity.

Customer Support: Provide technical expertise and consulting services to help clients select the right products.

By expanding from up to 80 product lines, the manufacturer can capture a larger share of the market, cater to diverse industries, and offer more specialized solutions, while also increasing operational complexity and requiring greater investment in R&D and supply chain management.

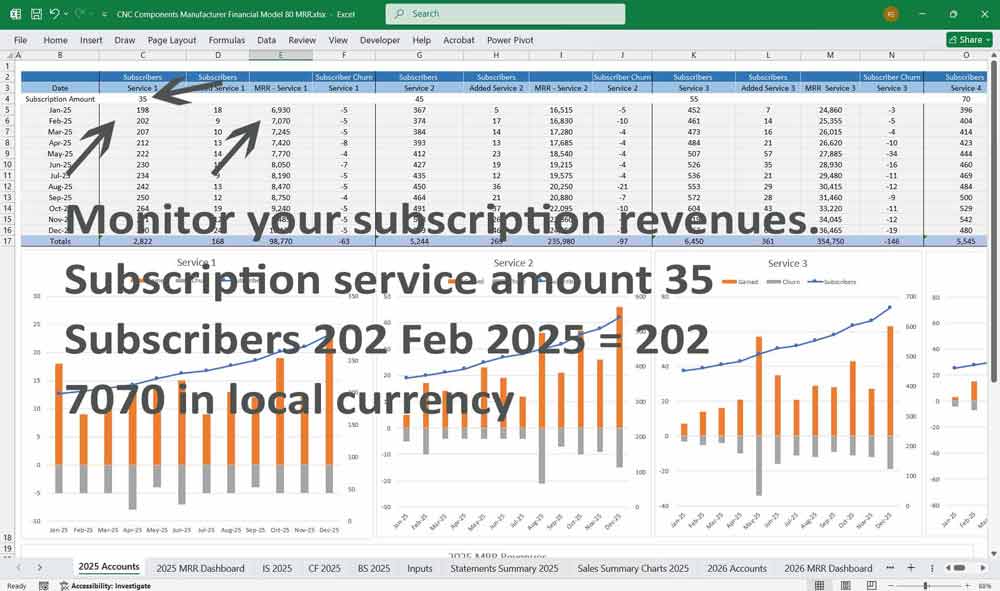

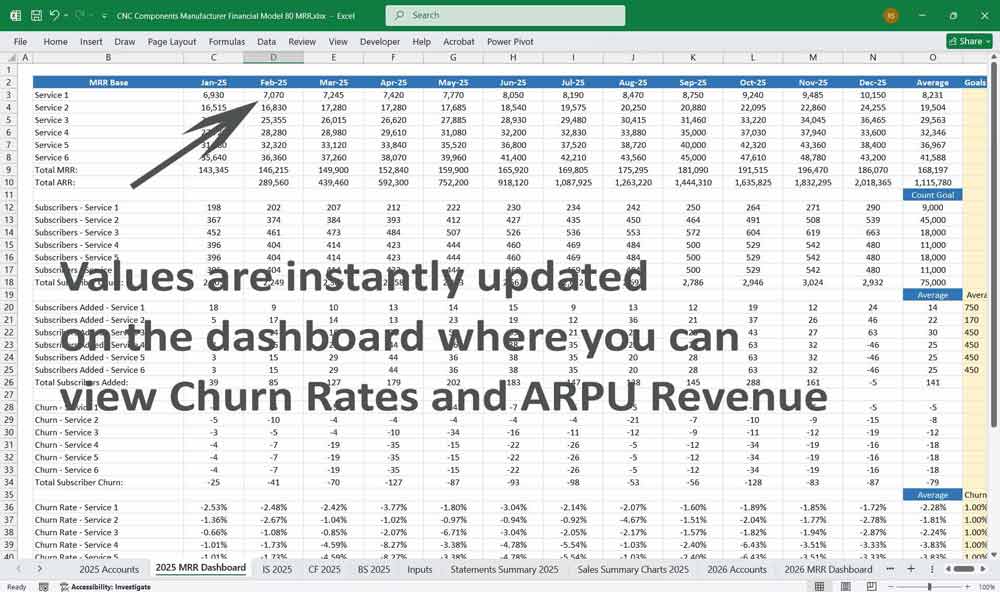

6-tier subscription model for a CNC Components manufacturer

This should cater to different customer needs, ranging from small-scale prototyping to large-volume production with premium services.

1. Basic Tier – CNC Prototype Starter

Price: Low

Target: Startups, small businesses, and R&D teams

Features:

- Access to a limited range of standard CNC components

- Low-volume prototyping (1-10 units per order)

- Basic materials (Aluminum, Stainless Steel, Mild Steel)

- Standard tolerances (+/- 0.1mm)

- Lead time: 10-15 business days

- Email support only

Ideal for: Early-stage product developers testing concepts

Standard Tier – Small Batch CNC Production

Price: Moderate

Target: Small manufacturers, product designers

Features:

- Expanded material options (Titanium, Brass, Copper)

- Medium-volume runs (10-100 units per order)

- Improved tolerances (+/- 0.05mm)

- Basic post-processing (anodizing, powder coating)

- Lead time: 7-10 business days

- Email + limited phone support

Ideal for: Small-scale production and functional prototypes

3. Professional Tier – Mid-Scale CNC Manufacturing

Price: Mid-range

Target: Growing manufacturers, automotive & aerospace suppliers

Features:

- Wide range of materials (including high-performance alloys)

- Mid-to-large volume runs (100-500 units per order)

- Precision machining (+/- 0.02mm tolerances)

- Advanced surface treatments (plating, heat treatment)

- Lead time: 5-7 business days

- Priority customer support (phone & email)

Ideal for: Businesses scaling up production with tighter tolerances

4. Enterprise Tier – High-Volume CNC Production

Price: High

Target: OEMs, industrial equipment manufacturers

Features:

- Bulk production (500-5,000 units per order)

- High-precision tolerances (+/- 0.01mm)

- Full-range finishing options (PVD coating, black oxide, laser marking)

- Dedicated account manager

- Expedited lead times (3-5 business days)

- Custom packaging and labeling

Ideal for: Large-scale manufacturing requiring reliability & speed

5. Premium Tier – Custom CNC Engineering & Assembly

Price: Premium

Target: Advanced manufacturing, aerospace, and medical industries

Features:

- Custom CNC component design & consultation

- Full assembly & integration support

- Ultra-precision machining (+/- 0.005mm)

- Certification support (ISO, AS9100, ITAR)

- Dedicated production line & priority scheduling

- 24/7 customer support & real-time tracking

Ideal for: Industries needing precision engineering and regulatory compliance

6. Elite Tier – Strategic CNC Manufacturing Partnership

Price: Exclusive (Custom Pricing)

Target: Global corporations, long-term CNC manufacturing partners

Features:

- Dedicated manufacturing facility access

- AI-driven supply chain optimization

- Fully customized materials & processes

- On-site quality control & inspections

- Exclusive engineering R&D collaboration

- Guaranteed lowest lead times & cost optimization

- Executive-level support & quarterly business reviews

Ideal for: Enterprises needing a full-scale, long-term manufacturing solution

Additional Considerations Across Tiers

Scalability:

Each tier is designed to be scalable, allowing customers to upgrade as their production needs grow.Integration & API Access:

Higher tiers offer greater levels of system integration, enabling seamless connectivity with in-house systems and real-time tracking.Flexibility:

Options for rollover of unused print credits and flexible overage billing ensure that customers only pay for what they need.Value-Added Services:

Complimentary design consultations, technical support, and training workshops become more prominent in the higher tiers, adding strategic value beyond just production capacity.Service Level Agreements (SLAs):

Defined SLAs across tiers provide transparency regarding turnaround times, quality standards, and uptime guarantees, with the most rigorous SLAs reserved for Enterprise and Premium tiers.

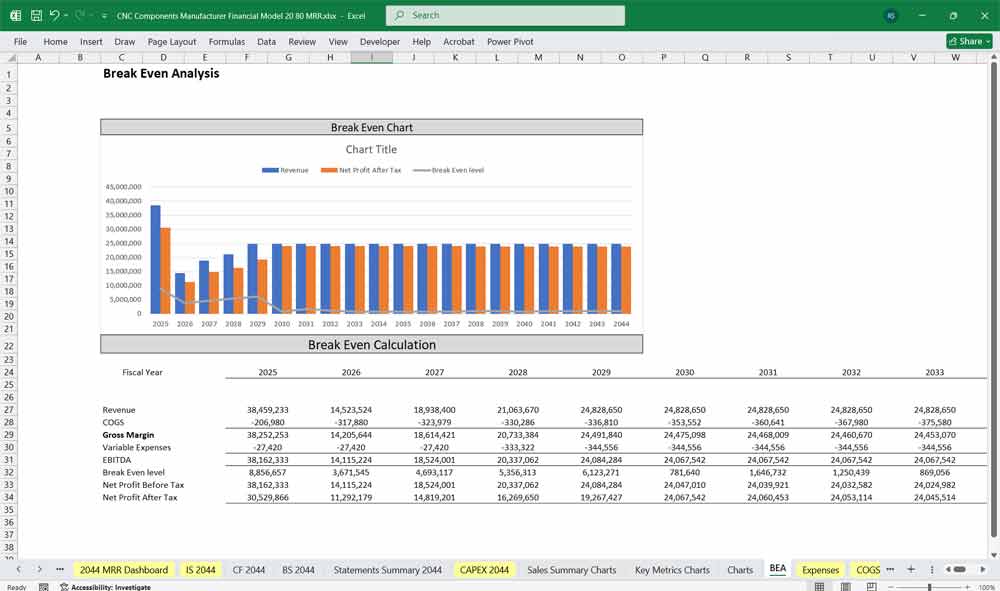

Final Notes on the Financial Model

Financial model for a CNC Components manufacturer

- Scenario Analysis: Create best-case, base-case, and worst-case projections.

- Break-even Analysis: Determine sales volume required to cover fixed & variable costs.

- Sensitivity Analysis: Assess how changes in raw material costs, pricing, or demand impact profitability.

These structured models and these finance models other help a CNC manufacturing service address a broad market spectrum, offering the right balance between cost, production capacity, support, and customization at each subscription level.

Download Link On Next Page