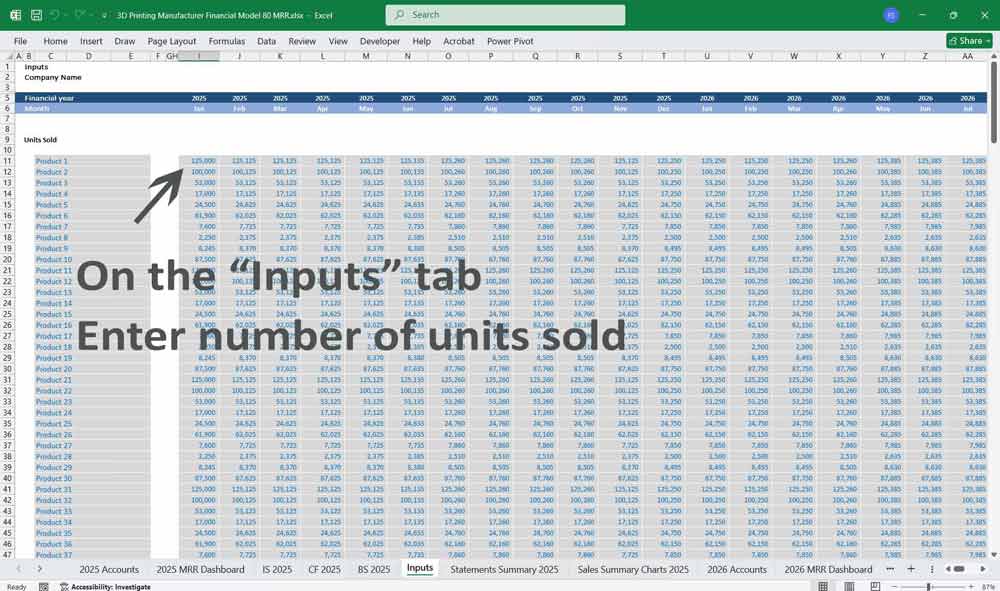

3D Printing Manufacturer Financial Model 20 Year Excel template

Here’s a comprehensive breakdown of the Excel Financial Models for a 3D Printing Manufacturer, covering the Income Statement, Cash Flow Statement, and Balance Sheet. With revenues from up to product lines and a Subscription Add-On. Cost structures and financial statements to forecast the financial health of your 3D (Additive Mfg) Printing. Looking for a CNC net shape parts model.

Financial Model for a 3D Printing (Additive Mfg) Manufacturer

Covering key components such as the Income Statement, Cash Flow Statement, and Balance Sheet.

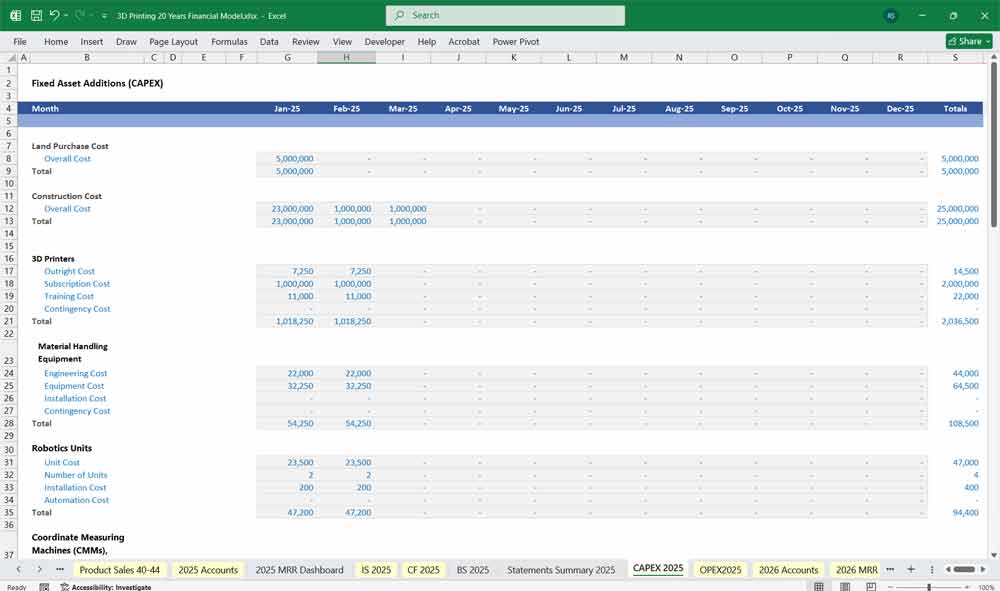

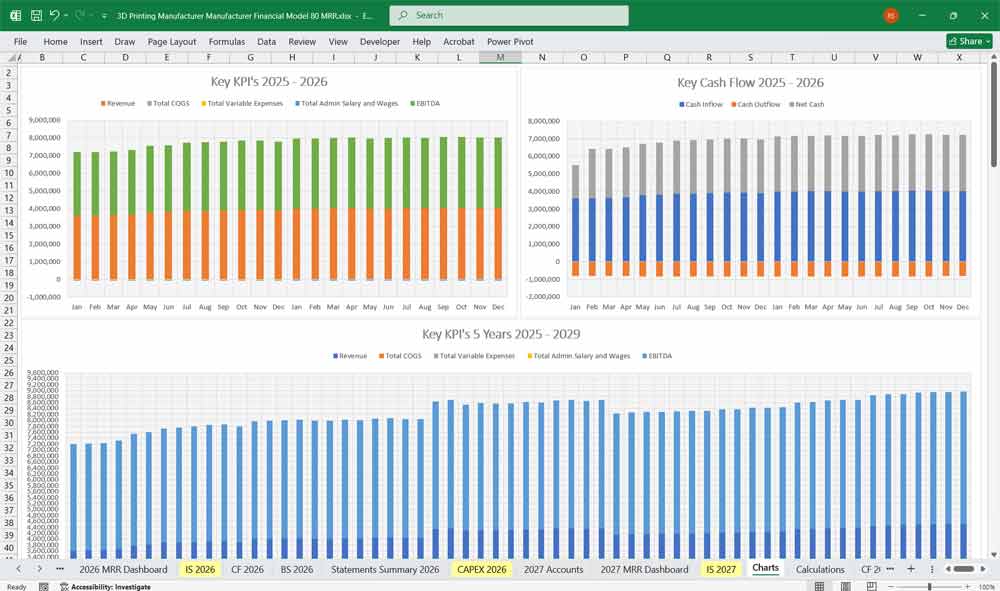

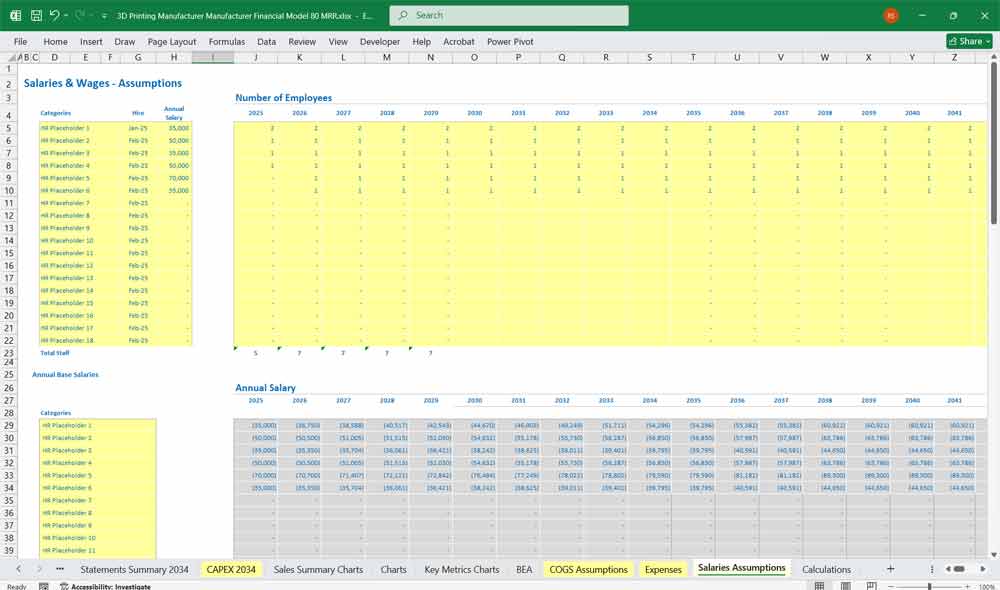

20x Income Statements, Cash Flow Statements, Balance Sheets, CAPEX Sheets, OPEX Sheets, Statement Summary Sheets, and Revenue Forecasting Charts with the specified revenue streams, BEA charts, sales summary charts, employee salary tabs and expenses sheets to help you manage your 3D Printing company finances.

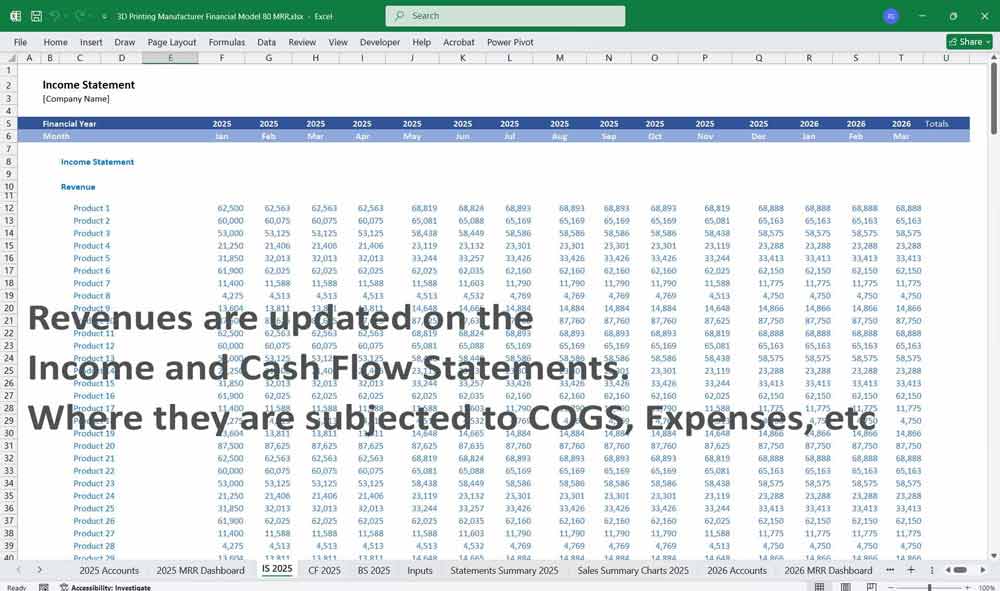

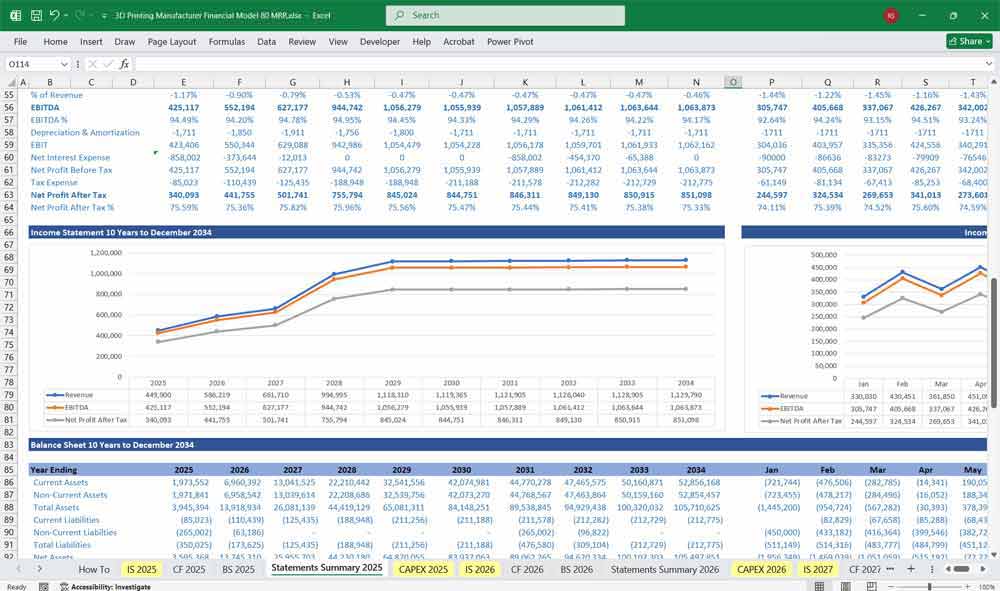

Income Statement (Profit & Loss Statement)

The Income Statement projects revenues, costs, and profitability over time.

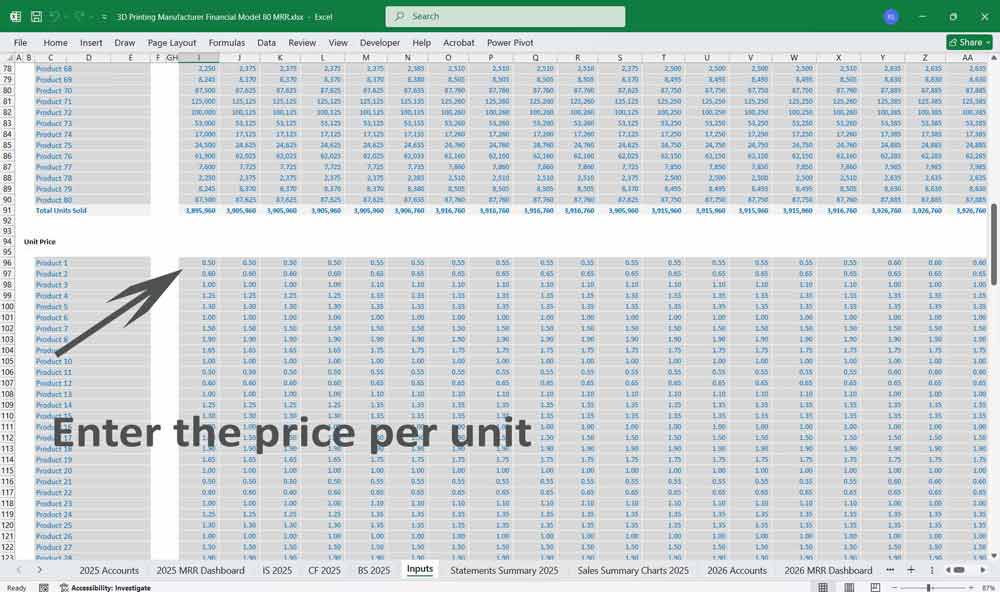

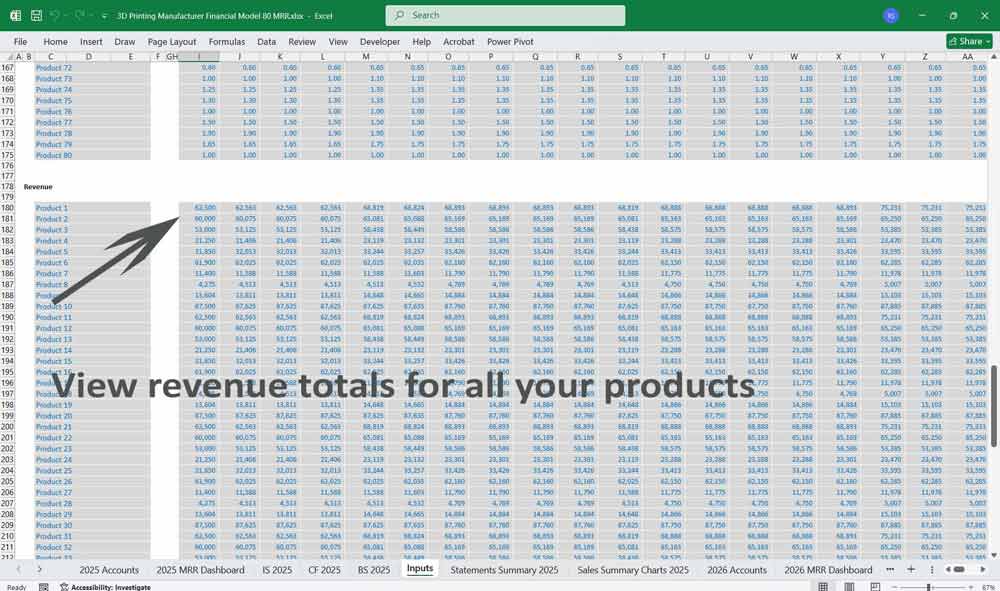

A. Revenue Streams

3D Printing Services Revenue

- Revenue from custom printing jobs for clients.

- Volume-based pricing or per-project basis.

Product Sales

- Sales of proprietary 3D-printed products (e.g., prototypes, consumer goods, spare parts).

- B2B and B2C segments.

Machine Sales

- If the company manufactures and sells 3D printers.

Material Sales

- Sales of proprietary filaments, resins, or powders used in 3D printing.

Software & Licensing Revenue

- If the company develops and sells proprietary 3D printing software.

Maintenance & Support Services

- Revenue from extended warranties, servicing, and maintenance contracts.

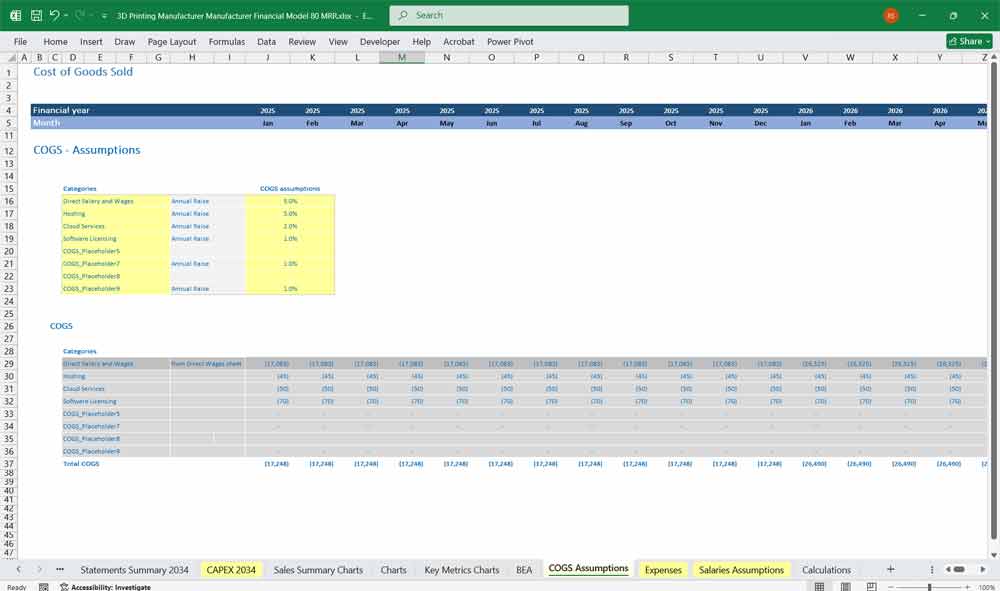

B. Cost of Goods Sold (COGS)

Raw Materials

- Filaments, powders, resins, and other consumables used in production.

Direct Labor

- Salaries of machine operators, engineers, and technicians involved in production.

Machine Depreciation & Maintenance

- Costs associated with maintaining and depreciating 3D printing equipment.

Utilities & Facility Costs

- Electricity, water, and other utilities required for operations.

C. Gross Profit

Gross Profit = Total Revenue – COGS

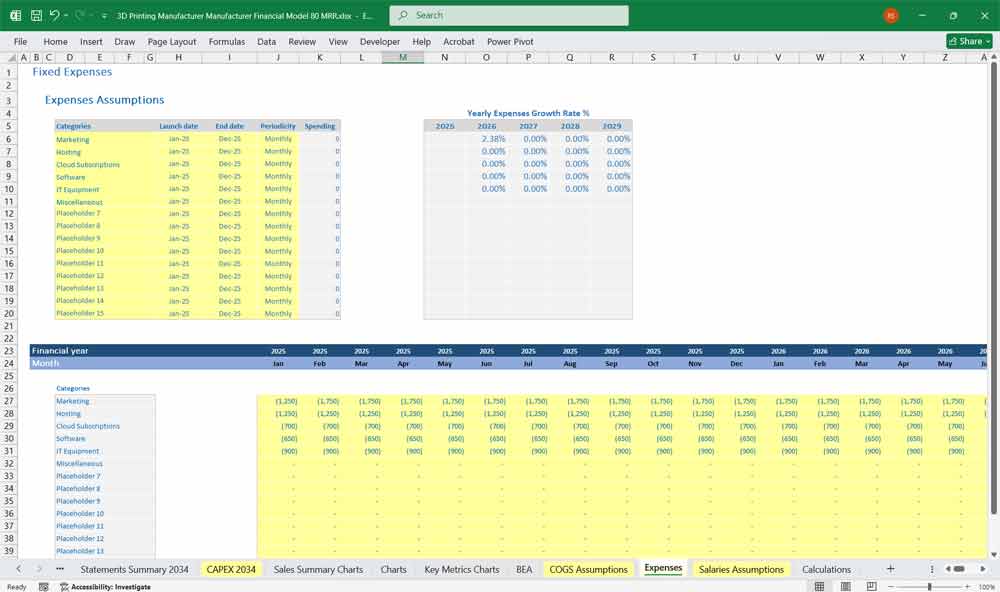

D. Operating Expenses (OPEX)

Sales & Marketing

- Advertising, promotions, digital marketing, trade shows, and sales commissions.

Research & Development (R&D)

- Costs for innovation, product design, and improving manufacturing processes.

General & Administrative (G&A) Expenses

- Salaries of management, HR, accounting, office rent, software, and insurance.

Technology & Software Costs

- CAD software, cloud storage, cybersecurity, and licensing fees.

E. EBITDA (Earnings Before Interest, Taxes, Depreciation & Amortization)

EBITDA = Gross Profit – Operating Expenses

F. Depreciation & Amortization

- Depreciation of 3D printers and manufacturing equipment.

- Amortization of software and patents.

G. EBIT (Earnings Before Interest & Taxes)

EBIT = EBITDA – Depreciation & Amortization

H. Interest Expense

- Interest on loans taken for purchasing equipment, R&D, or facility expansion.

I. Net Income (Profit or Loss)

Net Income = EBIT – Interest – Taxes

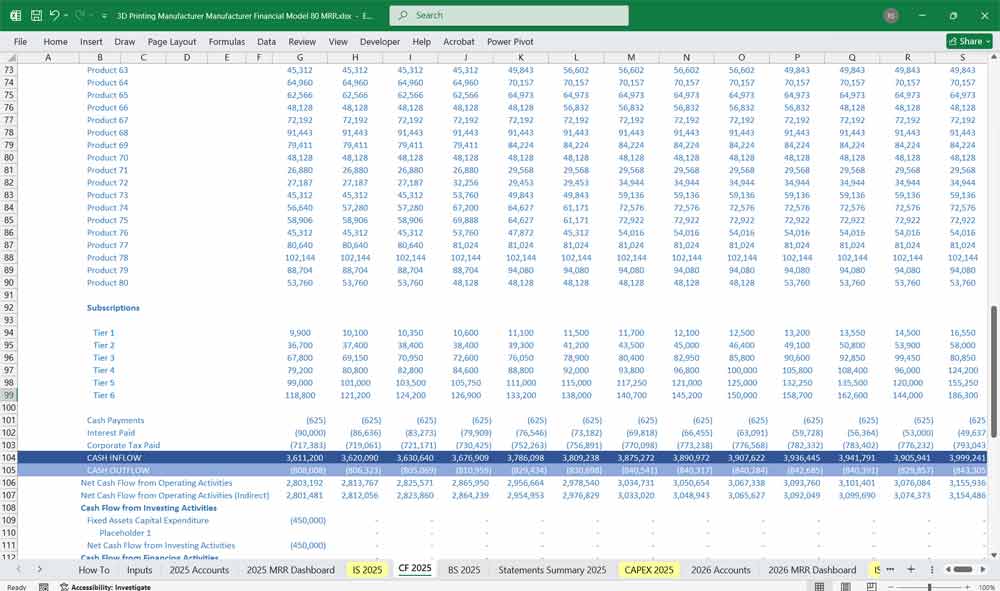

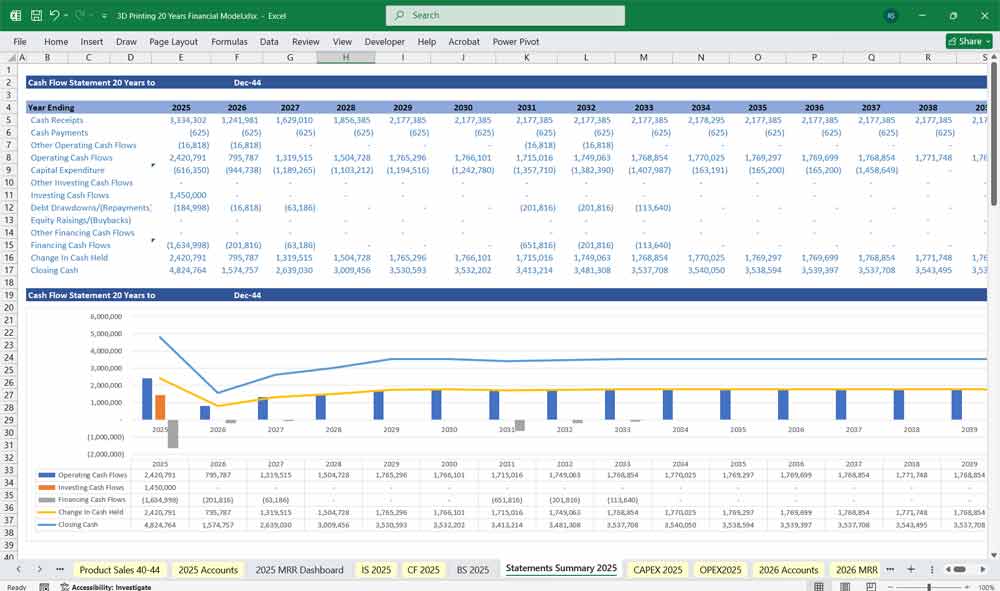

3D Printing Manufacturer Cash Flow Statement

Tracks the company’s cash inflows and outflows.

A. Cash Flow from Operating Activities

- Net Income (from the Income Statement)

- Adjustments for Non-Cash Expenses

- Depreciation & amortization.

- Changes in Working Capital

- Inventory Changes: If the company stocks 3D printing materials.

- Accounts Receivable Changes: If customers pay on credit.

- Accounts Payable Changes: Supplier payment cycles.

B. Cash Flow from Investing Activities

- Purchase of Equipment

- 3D printers, manufacturing tools, computers.

- Investment in Software & IP

- Development of proprietary 3D printing technology.

- Expansion Costs

- Setting up new production facilities.

- Sale of Equipment or Assets

- Disposing of outdated 3D printers.

C. Cash Flow from Financing Activities

- Debt Financing

- Loans taken for capital expenditures.

- Equity Financing

- Issuance of new shares for fundraising.

- Dividend Payments

- If applicable.

D. Net Change in Cash

Net Change in Cash = Cash Flow from Operating Activities + Cash Flow from Investing Activities + Cash Flow from Financing Activities

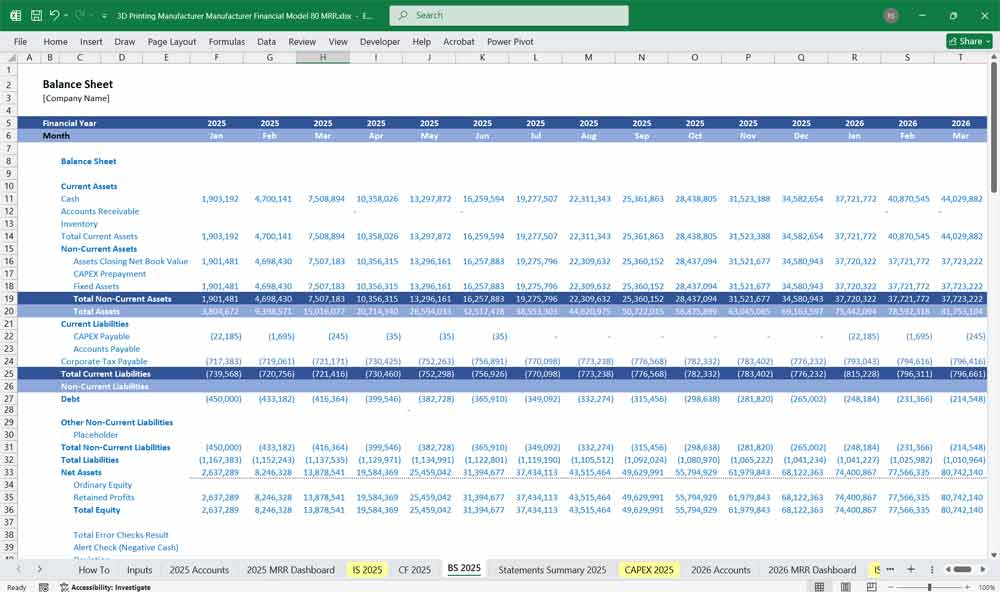

3d Printing Manufacturer Balance Sheet

Shows the company’s financial position at a given time.

A. Assets

Current Assets

- Cash & Cash Equivalents: Available liquidity.

- Accounts Receivable: Pending payments from customers.

- Inventory: Raw materials and finished goods.

Non-Current Assets

- Property, Plant & Equipment (PP&E): 3D printers, factory space.

- Intangible Assets: Patents, trademarks, proprietary software.

B. Liabilities

Current Liabilities

- Accounts Payable: Supplier dues.

- Short-Term Debt: Loans due within a year.

- Accrued Expenses: Wages, utilities, etc.

Long-Term Liabilities

- Long-Term Debt: Loans for capital investment.

- Deferred Tax Liabilities: Future tax obligations.

C. Shareholders’ Equity

- Common Stock

- Initial investment and shares issued.

- Retained Earnings

- Profits reinvested into the company.

Key Financial Metrics for a 3D Printing Manufacturer

- Gross Profit Margin = (Gross Profit / Revenue) × 100

- Operating Profit Margin (EBIT Margin) = (EBIT / Revenue) × 100

- Net Profit Margin = (Net Income / Revenue) × 100

- Return on Assets (ROA) = (Net Income / Total Assets) × 100

- Return on Equity (ROE) = (Net Income / Shareholder Equity) × 100

- Debt-to-Equity Ratio = (Total Debt / Shareholder Equity)

- Inventory Turnover = (COGS / Average Inventory)

- Days Sales Outstanding (DSO) = (Accounts Receivable / Revenue) × 365

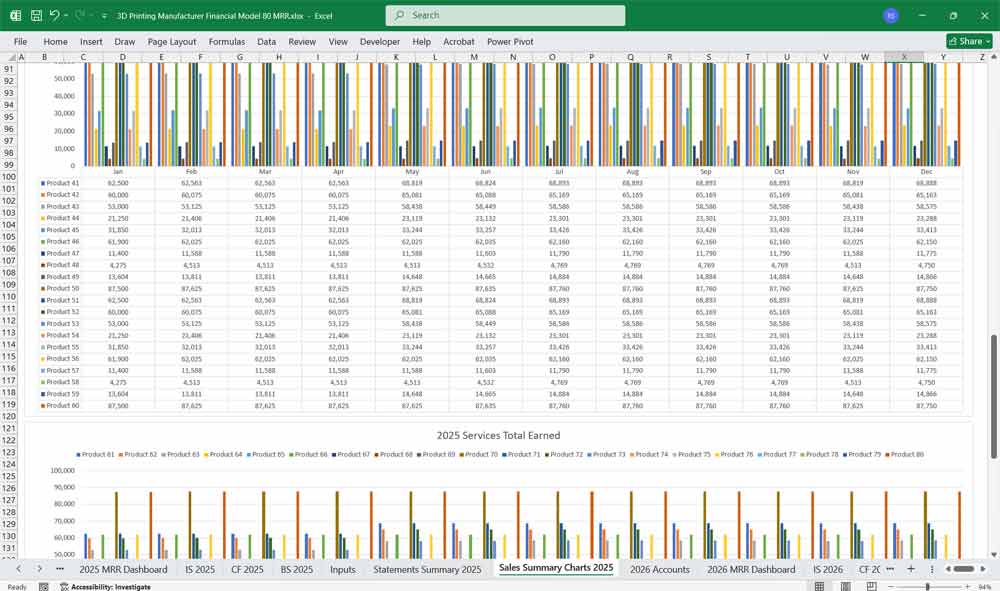

Smaller Product Lines Breakdown

This structure divides products into 4 primary categories, each with 10 subcategories.

Category 1: 3D Printers (10 Product Lines)

- Entry-Level FDM Printers – Affordable desktop models for hobbyists and beginners.

- Professional FDM Printers – High-resolution, industrial-grade FDM machines.

- High-Speed FDM Printers – Fast prototyping models with improved extrusion technology.

- Dual-Extrusion FDM Printers – Supports multi-material printing.

- Large-Format FDM Printers – Large build-volume printers for industrial applications.

- SLA Resin Printers – High-detail stereolithography printers for prototyping.

- DLP Resin Printers – Digital Light Processing printers with high-speed curing.

- SLS Powder Printers – Selective Laser Sintering for powder-based printing.

- Metal 3D Printers – DMLS or EBM for high-strength metal part production.

- Hybrid 3D Printers – Multi-technology machines combining CNC or injection molding.

Category 2: Materials & 3D Consumables (10 Product Lines)

- PLA Filaments – Standard eco-friendly filament options.

- ABS Filaments – High-durability filament for functional parts.

- PETG Filaments – Impact-resistant filament with good flexibility.

- Nylon Filaments – High-strength, wear-resistant printing materials.

- Flexible Filaments (TPU/TPE) – Rubber-like materials for elasticity.

- Carbon Fiber Filaments – Reinforced filaments for industrial applications.

- 3D Printing Resin Types (Standard, Engineering, Medical, Jewelry) – SLA-compatible materials.

- Metal Powders (Titanium, Stainless Steel, Aluminum, Copper) – For metal 3D printing.

- Support Materials (PVA, HIPS, Soluble Resins) – Dissolvable supports for complex prints.

- Custom Blends & Specialty Materials – Conductive, biocompatible, or ceramic materials.

Category 3: 3D Accessories & Upgrades (10 Product Lines)

- 3D Printing Build Plates (Glass, PEI, Carbon Fiber) – Surface options for print adhesion.

- Hotends & Nozzles (Hardened Steel, Ruby, Brass) – High-temperature, wear-resistant nozzles.

- 3d Printing Extruder Upgrades (Direct Drive, Bowden, High-Flow) – Optimized material extrusion.

- 3D Printing Enclosures & Air Filtration – Temperature control and fume extraction.

- Motion System Upgrades (Linear Rails, Belt Tensioners, Ball Screws) – For precision and speed.

- Cooling Solutions (Part Cooling Fans, Water Cooling, Active Airflow Systems) – Enhancing print quality.

- Auto-Bed Leveling Kits – Manual and automated calibration tools.

- Multi-Material & Color Upgrade Kits – Print with multiple colors/materials simultaneously.

- Wireless & Remote Printing Modules – IoT integration for cloud-based printing.

- 3D Printing Resin Handling & Curing Solutions (Wash Stations, UV Chambers) – Post-processing for resin prints.

Category 4: Software & 3D Printing Services (10 Product Lines)

- Slicing Software – Proprietary slicing solutions with AI optimization.

- 3D Cloud Printing & Remote Monitoring – Connectivity and workflow integration.

- Quality Control & Inspection Software – Ensuring print accuracy and reliability.

- AI-Powered Auto-Repair & Optimization Tools – Enhancing 3D print success rate.

- Firmware & Custom OS for Printers – Enhanced control and performance tuning.

- Educational Packages & Training Programs – Tutorials, workshops, and certification courses.

- 3D Print Model Libraries & Marketplaces – Digital asset store for 3D printing files.

- On-Demand 3D Printing Services – Print parts on request for customers.

- Enterprise Subscription Plans & Maintenance Services – Support packages for industries.

- R&D & Custom Printer Development Services – Bespoke solutions for specific applications.

80 Product Line Breakdown

To scale up to 80 product lines, the approach expands each category with 10 more subcategories and adds two new categories.

Expanded Core Categories

Each of the existing product lines is further divided into specialized subcategories, such as:

- More Filament Types (Conductive, Fire-Resistant, Self-Healing)

- More Printer Types (Food Printers, Bioprinting, Space-Ready 3D Printers)

- Expanded Post-Processing Tools (Electroplating, Smoothing, Painting Stations)

- More Software & AI Applications (Real-Time Defect Detection, Energy Efficiency Optimization)

New Categories

Category 5: Industry-Specific 3D Solutions (10 Product Lines)

- Automotive Prototyping Printers – High-strength materials for car parts.

- Aerospace & Defense Printers – Lightweight, high-temp materials for aerospace.

- Medical & Bioprinting Solutions – Specialized 3D printers for prosthetics and tissue engineering.

- Construction 3D Printers – Large-scale printers for concrete structures.

- Jewelry & Miniature Printing Solutions – High-detail resin printers for jewelry.

- Food Printers – 3D printers capable of printing chocolates, sugar, and edible designs.

- Textile & Wearable 3D Printing – Flexible, fabric-like materials for fashion.

- Robotics & Electronics 3D Printing – Conductive filaments for circuit-integrated prints.

- Furniture & Home Decor 3D Printing – Large-format printers for interior design.

- Sustainable & Recycled Material Printers – Using ocean plastics, bio-polymers, and recyclables.

Category 6: Advanced Manufacturing & 3D Automation (10 Product Lines)

- Multi-Axis 3D Printers – Robotic arms for non-planar 3D printing.

- Automated Print Farms & Print Clusters – Mass production solutions.

- AI & ML-Powered Print Optimization – Smart error detection and correction.

- 3D Printing & Injection Molding Hybrid Machines – Combining additive and traditional manufacturing.

- High-Resolution Nano 3D Printers – Ultra-small-scale 3D printing for microengineering.

- Integrated Robotics & Assembly Systems – Combining printing with assembly.

- Automation-Integrated Material Feeders – Real-time material switching and supply.

- Digital Twin Simulation for 3D Printing – Predictive modeling before printing.

- Mass-Customization Platforms for E-Commerce – Automated, on-demand manufacturing.

- Smart Factory & Industrial IoT Integration – Full-scale automation solutions.

More Expansion Options to Reach 80

61-80:

Expanding into niche markets, new technologies, and integrated 3D solutions

such as:

- Sustainable 3D printing initiatives

- AI-powered defect recognition

- Specialized military and disaster relief 3D printing

- Recycling-based filament production lines

- Fully autonomous robotic 3D printing stations

Final Thoughts

This modular approach enables growth from 80 product lines while staying organized, scalable, and market-driven.

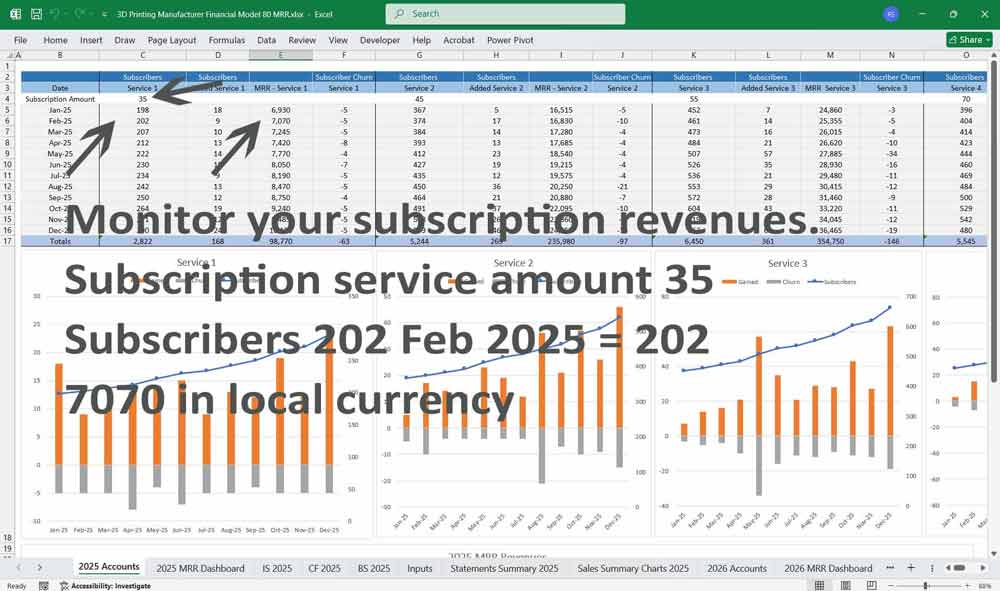

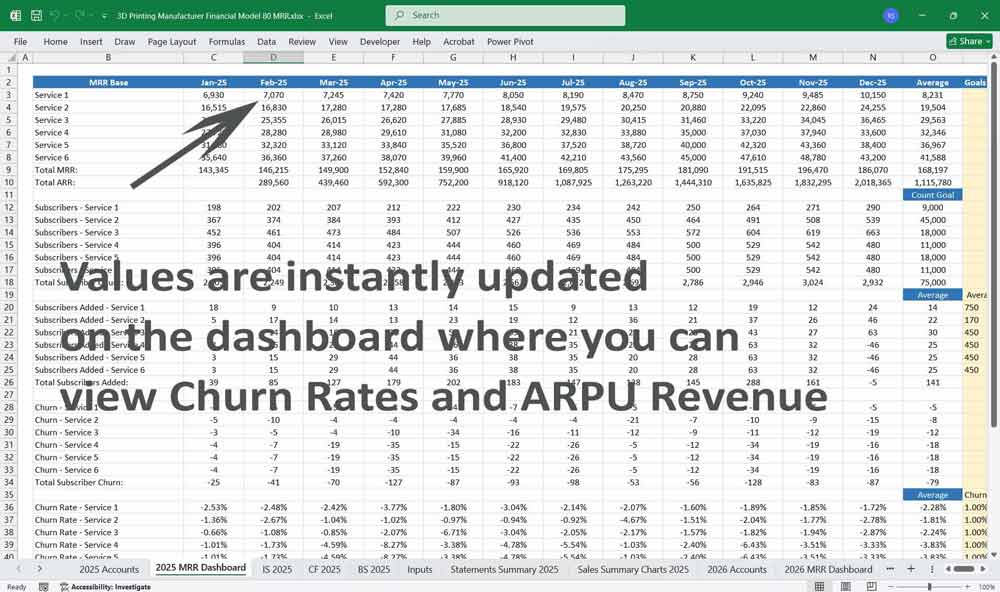

6-Tier Subscription Model for a 3D Printing Manufacturer

This is structured to cater to different customer segments, ranging from hobbyists to large enterprises. Below is a detailed breakdown of the tiers, including pricing, features, and benefits.

Tier 1: Basic / 3D Printing Starter

Target Customer:

Individuals, hobbyists, and small startups seeking to experiment with 3D printing without large upfront costs.Key Features:

- Monthly Print Credits: A modest allotment (e.g., 10–20 small-scale print jobs).

- Material Options: Limited selection (standard plastics and basic resins).

- Print Resolution & Speed: Standard quality with longer turnaround times.

- Support: Access to a self-service online portal and FAQs.

- Customization: Basic file review and automated error-checking.

Pricing & Commitment:

- Low monthly fee with no long-term commitment.

- Overages billed on a per-print basis.

Tier 2: Standard / 3D Printing Essential

Target Customer:

Small businesses and professionals needing a reliable service for moderate-volume printing.Key Features:

- Monthly Print Credits: Increased allotment (e.g., 30–50 print jobs).

- Material Options: Expanded library including specialty plastics and limited metal/resin options.

- Enhanced Print Quality: Faster turnaround with mid-range print resolution.

- Support: Email and chat support during business hours.

- Customization: Priority review of submitted designs with minor adjustments.

Pricing & Commitment:

- Moderate monthly fee with potential discounts on volume overages.

- Option for a quarterly subscription plan for additional savings.

Tier 3: 3D Printing Professional

Target Customer:

Designers and companies with regular 3D printing needs and higher quality expectations.Key Features:

- Monthly Print Credits: Higher volume (e.g., 75–100 print jobs).

- Material Options: Broad selection including advanced composites and high-durability materials.

- Print Resolution & Speed: High-definition prints with expedited turnaround times.

- Support: Dedicated support line and priority email/chat support.

- Customization: Personalized design feedback and minor custom feature integration.

- Additional Services: API access for automating print requests and integration with design software.

Pricing & Commitment:

- Premium monthly fee with annual plan options offering cost efficiency.

Tier 4: 3D Printing Business

Target Customer:

Growing companies requiring scalable production, tighter integration, and higher consistency.Key Features:

- Monthly Print Credits: Scalable printing capacity with rollover options.

- Material Options: Full material catalog, including experimental and custom material formulations.

- Print Resolution & Speed: Priority queue status ensuring fast turnarounds even during peak times.

- Support: 24/7 customer support with a dedicated account manager.

- Customization: Tailored workflow integration and enhanced design consultancy services.

- Operational Integration: Integration with clients’ ERP systems for automated ordering and tracking.

Pricing & Commitment:

- Higher monthly fee with volume discounts and multi-year subscription incentives.

Tier 5: 3D Printing Enterprise

Target Customer:

Large enterprises with complex production needs and high-volume, continuous 3D printing operations.Key Features:

- Monthly Print Credits: Customizable, virtually unlimited production capacity subject to SLA limits.

- Material Options: Fully customizable material options including R&D collaborations for new materials.

- Print Resolution & Speed: Ultra-fast production with highest quality settings available.

- Support: Dedicated technical support team, on-site assistance, and white glove service.

- Customization: Fully tailored solutions including design assistance, prototype development, and iterative production.

- Integration & Reporting: Advanced analytics, full API integration, and comprehensive reporting dashboards.

Pricing & Commitment:

- Custom pricing structure based on usage, volume, and service level agreements.

- Multi-year contracts with flexible payment terms.

Tier 6: Premium / 3d Printing Ultimate

Target Customer:

Organizations or innovators pushing the boundaries of 3D manufacturing who require exclusive, state-of-the-art service.Key Features:

- Monthly Print Credits: Unlimited production with prioritized scheduling.

- Material Options: Access to experimental materials, proprietary blends, and cutting-edge composites.

- Print Resolution & Speed: Maximum achievable resolution and fastest turnaround times with dedicated production lines.

- Support: Elite 24/7 concierge support, including a dedicated team for R&D and innovation projects.

- Customization: Custom-built solutions, direct involvement in product design improvements, and co-development opportunities.

- Strategic Partnership: Priority access to new technologies, beta testing opportunities, and strategic advisory services.

Pricing & Commitment:

- Highest tier pricing based on bespoke service agreements.

- Typically, it requires an enterprise-level, long-term commitment with flexible terms tailored to strategic objectives.

Additional Considerations Across Tiers

Scalability:

Each tier is designed to be scalable, allowing customers to upgrade as their production needs grow.Integration & API Access:

Higher tiers offer greater levels of system integration, enabling seamless connectivity with in-house systems and real-time tracking.Flexibility:

Options for rollover of unused print credits and flexible overage billing ensure that customers only pay for what they need.Value-Added Services:

Complimentary design consultations, technical support, and training workshops become more prominent in the higher tiers, adding strategic value beyond just production capacity.Service Level Agreements (SLAs):

Defined SLAs across tiers provide transparency regarding turnaround times, quality standards, and uptime guarantees, with the most rigorous SLAs reserved for Enterprise and Premium tiers.

Final Notes on the Financial Model

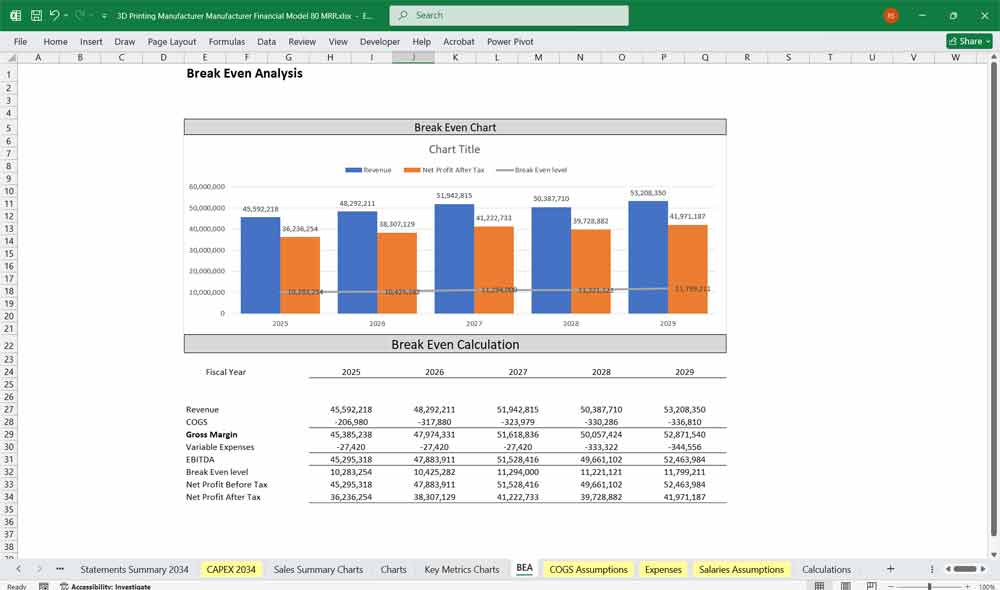

10 Year Financial model for a 3D Printing manufacturer

- Scenario Analysis: Create best-case, base-case, and worst-case projections.

- Break-even Analysis: Determine sales volume required to cover fixed & variable costs.

- Sensitivity Analysis: Assess how changes in raw material costs, pricing, or demand impact profitability.

This structured model, along with other financial templates, helps a 3D manufacturing service address a broad market spectrum, offering the right balance between cost, production capacity, support, and customization at each subscription level.

Download Link On Next Page