Robotics Manufacturer Financial Model

This 20-Year 3 Statement MS Excel Robotics Manufacturer Financial Model covers the Income Statement, Cash Flow Statement, and Balance Sheet. With revenues from up to 80 product lines and a Subscription Add-On. Cost structures and financial statements to forecast the financial health of your Robotics Manufacturing.

Financial Model for a Robotics Manufacturer

These financial models for a robotics manufacturer provide a structured forecast of revenues, expenses, and financial performance. They include core financial statements and key assumptions related to production, sales, costs, and capital investments.

Revenue Streams

The company’s revenue primarily comes from:

- Product Sales:

- Lower Product Lines (Entry-Level & Mid-Tier Robots)

- 80 Product Lines (Mid-Tier & High-End Robots)

- Service & Maintenance Contracts

- Software & Licensing

- Customization & R&D Services

- Spare Parts & Accessories

- Government & Commercial Contracts

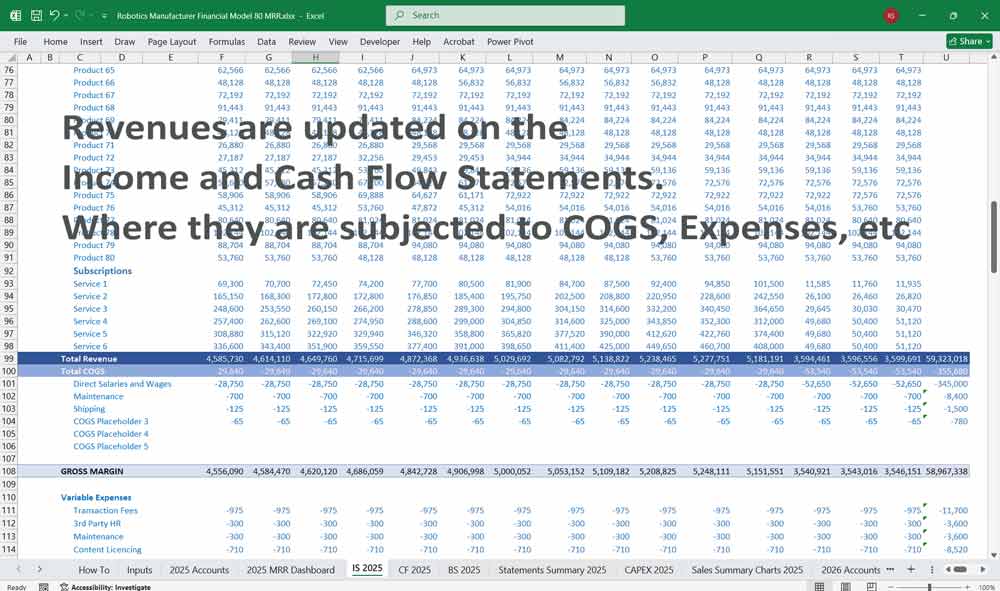

Income Statement (Profit & Loss Statement)

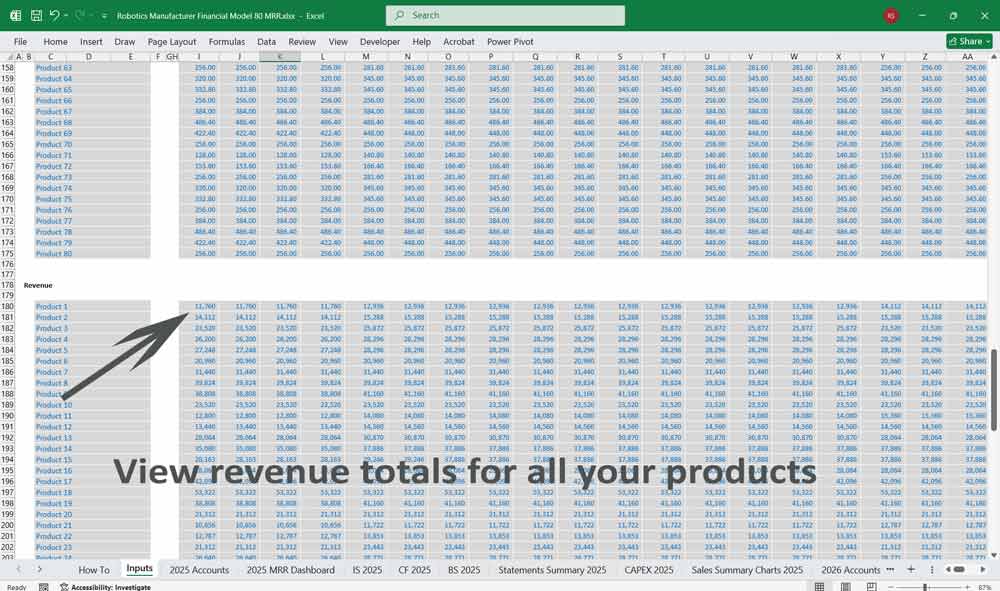

Revenue

Smaller Product Lines Revenue:

- Average Selling Price (ASP) per unit = $30,000

- Units Sold per Year = 10,000

- Total Revenue = $300M

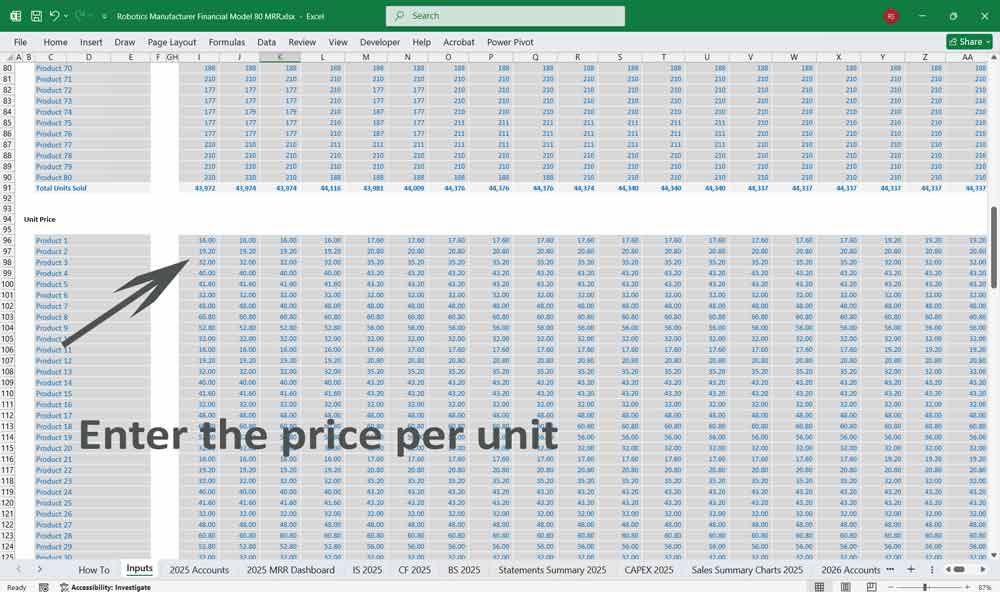

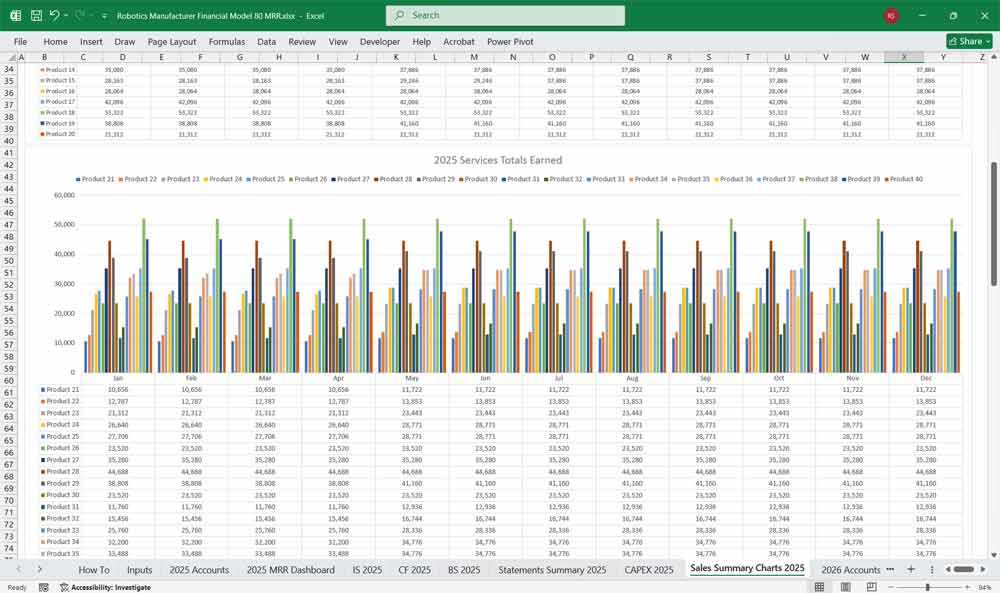

80 Product Lines Revenue:

- ASP per unit = $50,000

- Units Sold per Year = 8,000

- Total Revenue = $400M

Other Revenue Streams:

- Service & Maintenance = $50M

- Software & Licensing = $30M

- Customization & R&D = $40M

- Spare Parts & Accessories = $25M

- Government & Commercial Contracts = $55M

- Total Additional Revenue = $200M

Total Revenue

$300M + $400M + $200M = $900M

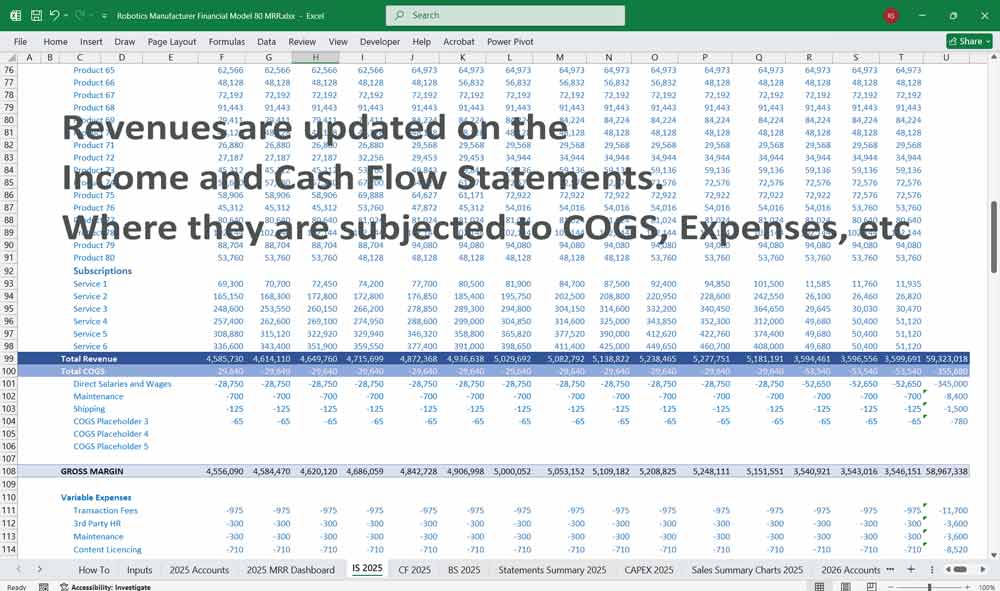

Cost of Goods Sold (COGS)

- Material Costs: $250M

- Labor Costs: $120M

- Manufacturing Overheads: $80M

- Total COGS = $450M

Gross Profit

$900M – $450M = $450M

Gross Profit Margin = 50%

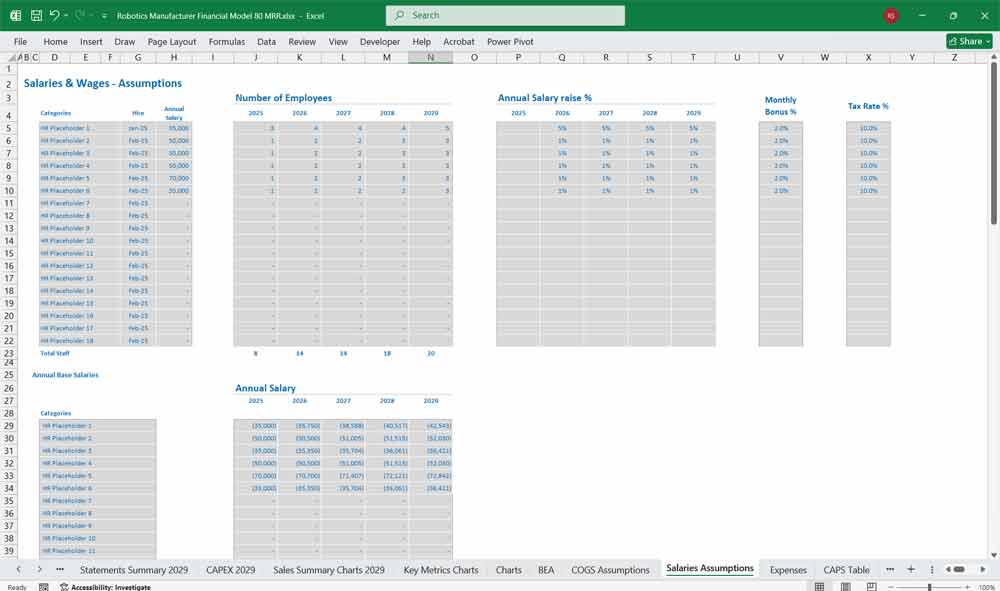

Operating Expenses (OPEX)

- R&D: $100M

- Sales & Marketing: $80M

- General & Admin (G&A): $70M

- Total OPEX = $250M

Operating Profit (EBIT)

$450M – $250M = $200M

Other Expenses

- Interest Expenses: $20M

- Depreciation & Amortization: $30M

- Taxes (25% Effective Rate): $37.5M

Net Profit

$200M – ($20M + $30M + $37.5M) = $112.5M

Net Profit Margin = 12.5%

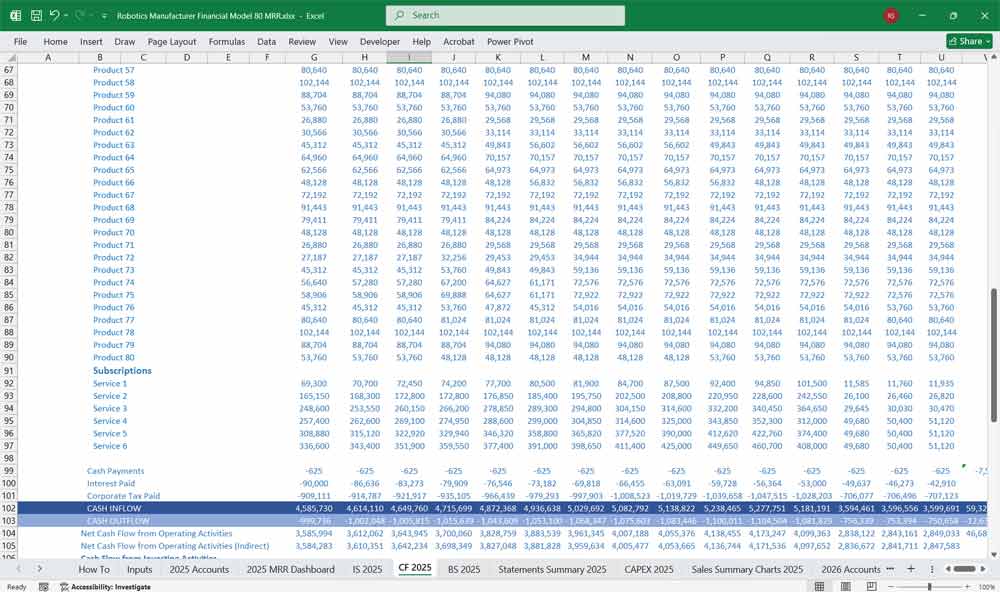

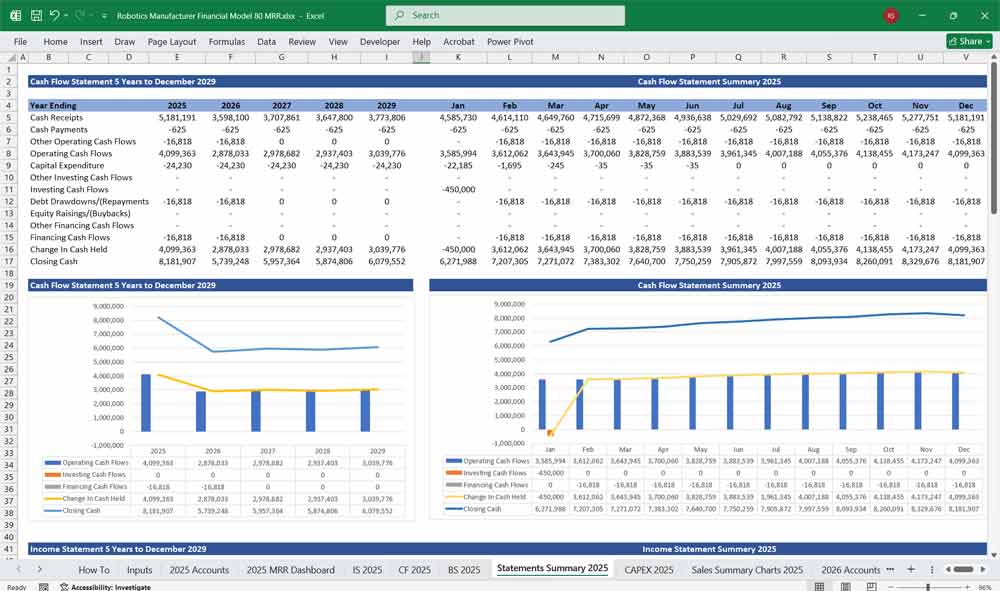

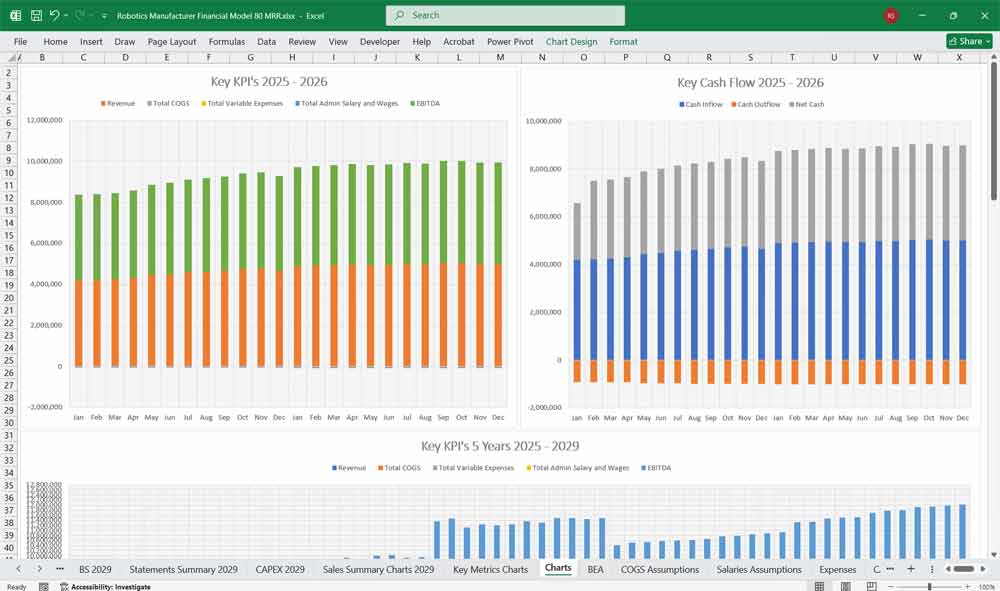

Robotics Manufacturer Cash Flow Statement

Operating Cash Flow

- Net Income: $112.5M

- Add: Depreciation & Amortization: $30M

- Add: Change in Working Capital: ($15M)

- Inventory Changes: ($10M)

- Accounts Receivable: ($5M)

- Net Cash Flow from Operations = $127.5M

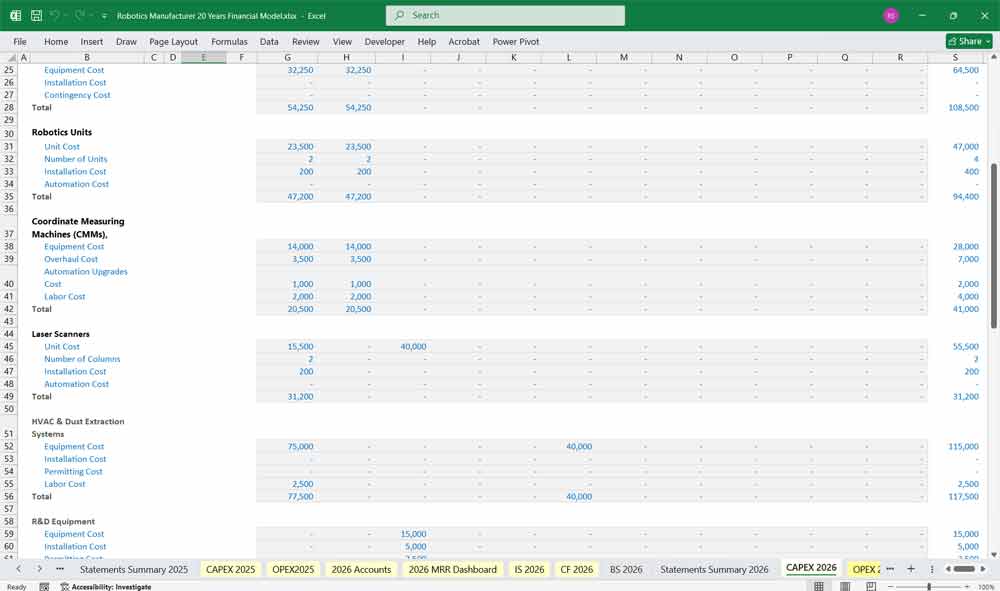

Investing Cash Flow

- Capital Expenditures (CAPEX): ($80M)

- Investments in R&D: ($50M)

- Net Cash Flow from Investing = ($130M)

Financing Cash Flow

- Issuance of Debt: $50M

- Debt Repayment: ($30M)

- Dividends Paid: ($20M)

- Net Cash Flow from Financing = $0M

Total Net Cash Flow

$127.5M – $130M + $0M = ($2.5M)

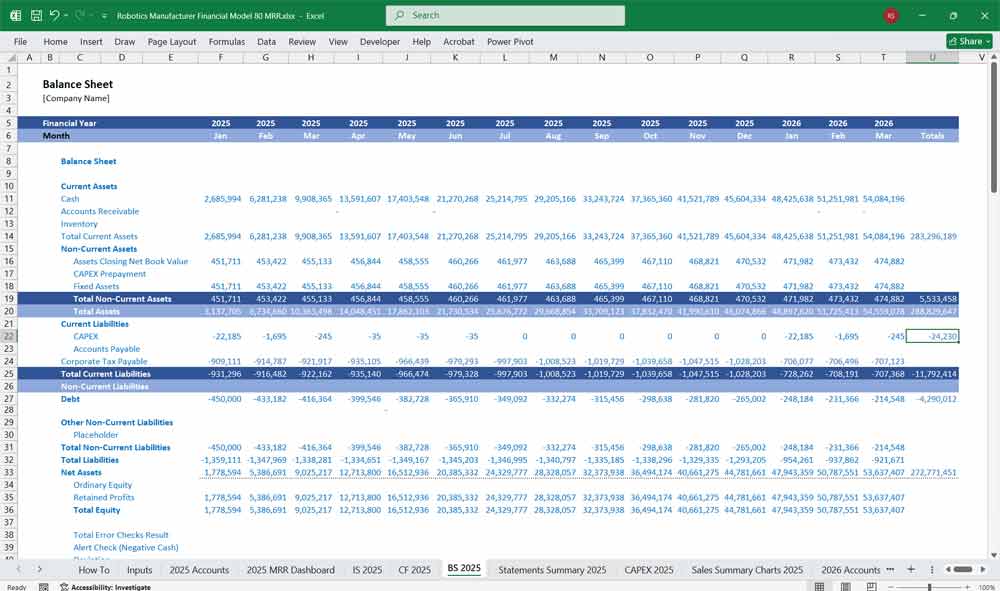

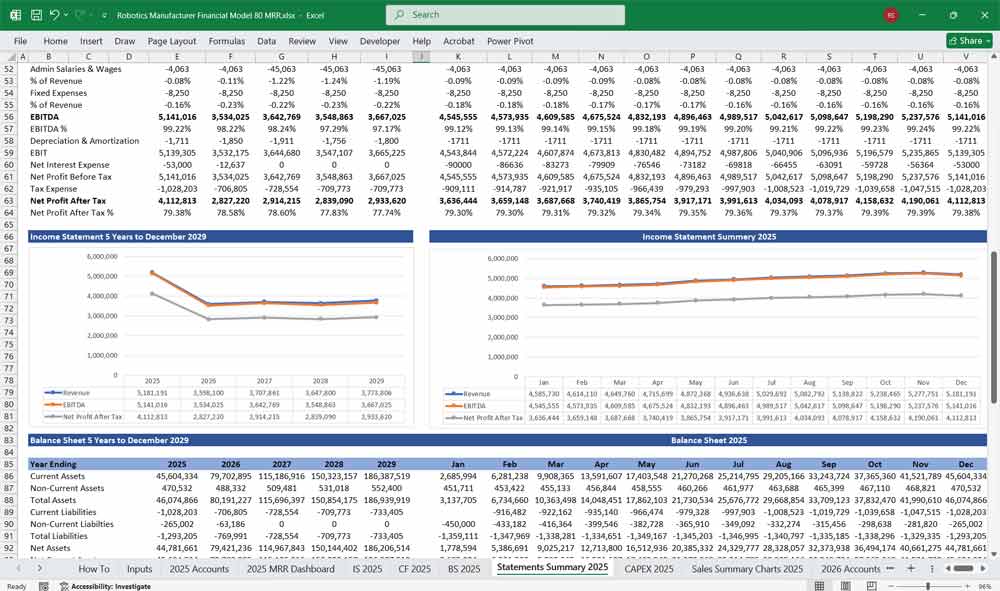

Robotics Manufacturer Balance Sheet

Assets

Current Assets

- Cash & Cash Equivalents: $100M

- Accounts Receivable: $80M

- Inventory: $90M

- Prepaid Expenses: $10M

- Total Current Assets = $280M

Non-Current Assets

- Property, Plant & Equipment (PP&E): $300M

- Intangible Assets (Patents, Software): $150M

- Long-Term Investments: $50M

- Total Non-Current Assets = $500M

Total Assets = $780M

Liabilities & Equity

Current Liabilities

- Accounts Payable: $70M

- Short-Term Debt: $60M

- Accrued Expenses: $40M

- Total Current Liabilities = $170M

Non-Current Liabilities

- Long-Term Debt: $200M

- Deferred Tax Liabilities: $50M

- Total Non-Current Liabilities = $250M

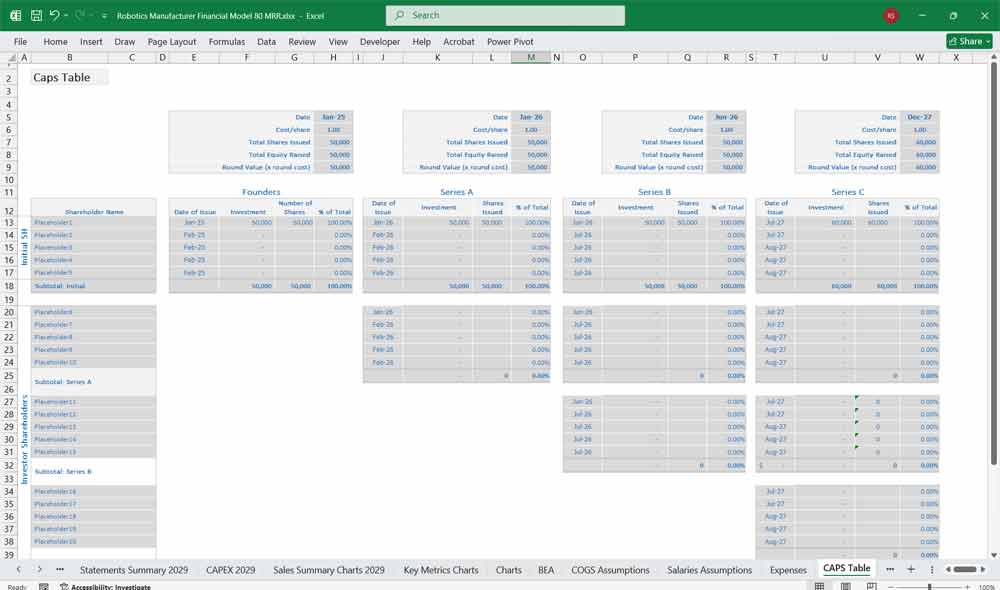

Shareholders’ Equity

- Common Stock: $100M

- Retained Earnings: $260M

- Total Equity = $360M

Total Liabilities & Equity = $780M

Key Financial Metrics for a Robotics Manufacturer

- Gross Profit Margin = (Gross Profit / Revenue) × 100

- Operating Profit Margin (EBIT Margin) = (EBIT / Revenue) × 100

- Net Profit Margin = (Net Income / Revenue) × 100

- Return on Assets (ROA) = (Net Income / Total Assets) × 100

- Return on Equity (ROE) = (Net Income / Shareholder Equity) × 100

- Debt-to-Equity Ratio = (Total Debt / Shareholder Equity)

- Inventory Turnover = (COGS / Average Inventory)

- Days Sales Outstanding (DSO) = (Accounts Receivable / Revenue) × 365

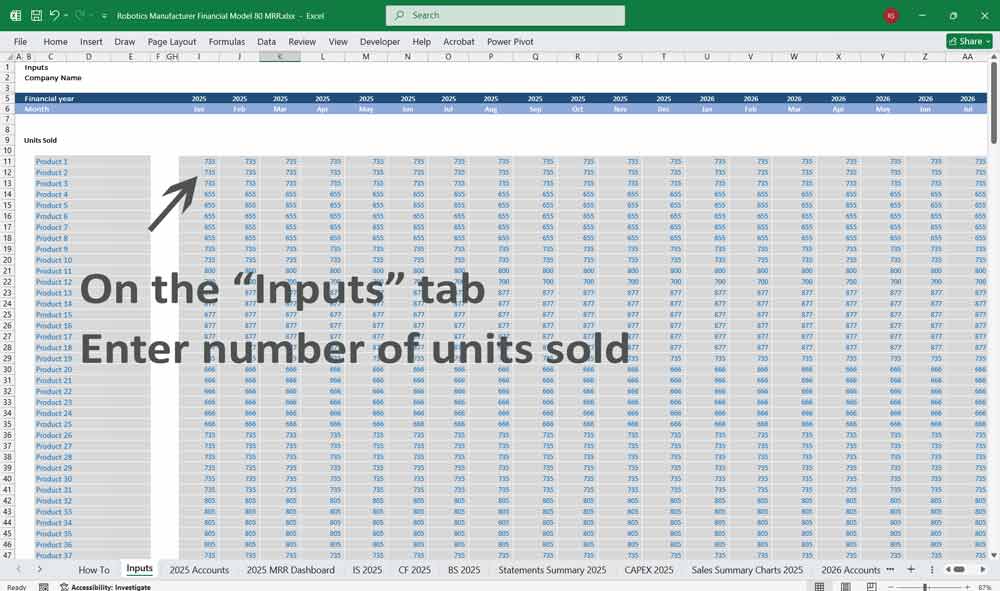

When structuring product lines for a robotics manufacturer, it’s important to organize them in a way that aligns with customer needs, market demand, and operational efficiency. Below are detailed sections for up to 80 product lines on the Robotics Manufacturer Financial Model, including categorization, examples, and strategic considerations.

Product Line Categorization for a Robotics Manufacturer

A Robotics Manufacturer typically produces a wide range of products for different industries, including construction, automotive, consumer goods, and specialty applications.

1. Assembly Line Robotics

Product Ideas:

Robotic arms for assembling electronics (e.g., smartphones, laptops).

Precision welding robots for automotive manufacturing.

Screw-driving robots for fastening components.

Applications: Automotive, electronics, consumer goods.

Key Features: High precision, repeatability, and speed.

2. Material Handling Robotics

Product Ideas:

Automated guided vehicles (AGVs) for transporting goods in warehouses.

Robotic forklifts for pallet handling.

Conveyor belt sorting robots.

Applications: Logistics, e-commerce, manufacturing.

Key Features: Load capacity, navigation systems, and safety features.

3. Painting and Coating Robotics

Product Ideas:

Robotics for spray-painting cars or industrial equipment.

Coating robots for applying protective layers to metal parts.

Applications: Automotive, aerospace, construction.

Key Features: Uniform coating, reduced waste, and compliance with safety standards.

4. Inspection and Quality Control Robots

Product Ideas:

Vision-based robotic systems for inspecting product defects.

Robots for measuring dimensions and tolerances.

AI-powered robots for identifying quality issues in real-time.

Applications: Manufacturing, pharmaceuticals, food processing.

Key Features: High-resolution cameras, AI algorithms, and precision sensors.

5. Heavy-Duty Robotics

Product Ideas:

Robotics for lifting and moving heavy machinery.

Demolition robots for construction sites.

Robotic exoskeletons for assisting workers in lifting heavy objects.

Applications: Construction, mining, shipbuilding.

Key Features: High load capacity, durability, and safety mechanisms.

Product Line 80: Service Robots

Service robots are designed for non-industrial applications, such as healthcare, hospitality, and domestic use. These robots are typically smaller, more versatile, and user-friendly.

1. Healthcare Robotics

Product Ideas:

Surgical robotics for minimally invasive procedures.

Robotic assistants for patient care (e.g., lifting patients, delivering medications).

Telepresence robots for remote consultations.

Applications: Hospitals, clinics, elderly care facilities.

Key Features: Sterilization, precision, and ease of use.

2. Domestic Robots

Product Ideas:

Robotic vacuum cleaners (e.g., advanced Roomba models).

Lawn-mowing robots for automated garden maintenance.

Window-cleaning robots for high-rise buildings.

Applications: Residential homes, commercial buildings.

Key Features: Autonomous navigation, energy efficiency, and user-friendly interfaces.

3. Hospitality Robots

Product Ideas:

Robotic waiters for serving food in restaurants.

Concierge robots for hotels (e.g., check-in, room service).

Cleaning robots for maintaining public spaces.

Applications: Hotels, restaurants, airports.

Key Features: Human-like interaction, mobility, and reliability.

4. Logistics and Delivery Robotics

Product Ideas:

Last-mile delivery robotics for e-commerce companies.

Drones for delivering medical supplies in remote areas.

Autonomous robots for sorting packages in warehouses.

Applications: E-commerce, healthcare, logistics.

Key Features: Navigation in complex environments, payload capacity, and battery life.

5. Educational and Entertainment Robots

Product Ideas:

Programmable robots for teaching coding and robotics to students.

Companion robots for children with interactive features.

Robotic toys with AI capabilities (e.g., voice recognition, games).

Applications: Schools, homes, entertainment venues.

Key Features: Educational value, interactivity, and affordability.

6. Agricultural Robotics

Product Ideas:

Harvesting robotic tools for picking fruits and vegetables.

Weed-removal robotics for precision farming.

Drones for monitoring crop health and spraying pesticides.

Applications: Farming, horticulture, vineyards.

Key Features: Weather resistance, precision, and scalability.

7. Security and Surveillance Robotics

Product Ideas:

Patrol robots for monitoring warehouses and factories.

Drones for aerial surveillance in large areas.

AI-powered robotics for detecting intruders or anomalies.

Applications: Security firms, industrial facilities, public spaces.

Key Features: Real-time monitoring, threat detection, and autonomous operation.

8. Cleaning and Sanitization Robotics

Product Ideas:

Robotic systems for disinfecting hospitals and public spaces.

Floor-scrubbing robots for commercial buildings.

Robotic systems for cleaning solar panels.

Applications: Healthcare, hospitality, energy.

Key Features: Sanitization efficiency, autonomous navigation, and durability.

9. Personal Robotic Assistants

Product Ideas:

Voice-activated robots for managing schedules and tasks.

Robotic companions for elderly or disabled individuals.

Robots for organizing and decluttering homes.

Applications: Residential homes, elderly care, offices.

Key Features: Voice recognition, mobility, and user-friendly design.

10. Environmental Robot Drones

Product Ideas:

Robots for cleaning oceans and rivers (e.g., collecting plastic waste).

Drones for monitoring deforestation and wildlife.

Robots for planting trees in deforested areas.

Applications: Environmental conservation, wildlife protection.

Key Features: Sustainability, adaptability, and remote operation.

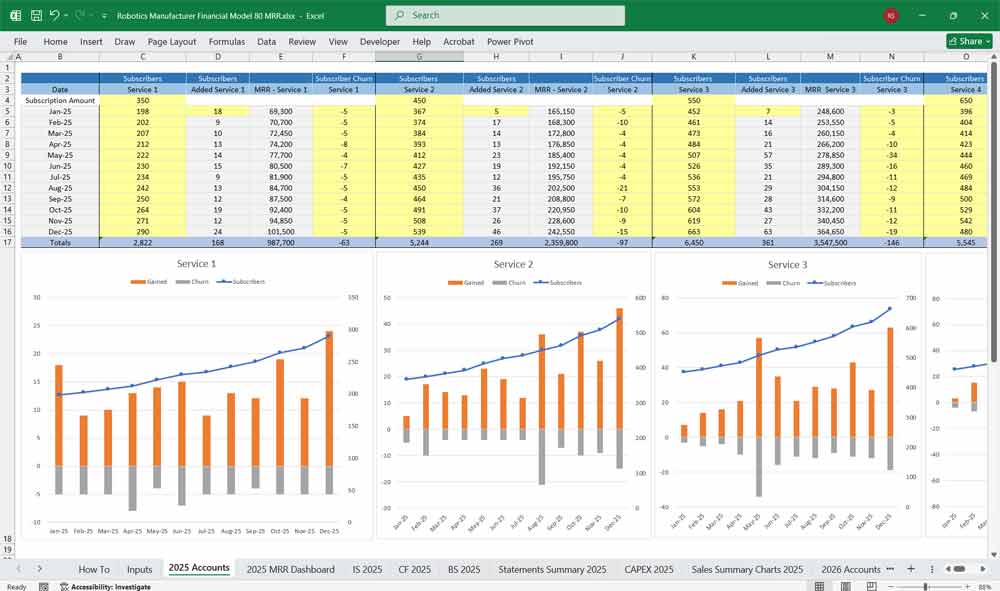

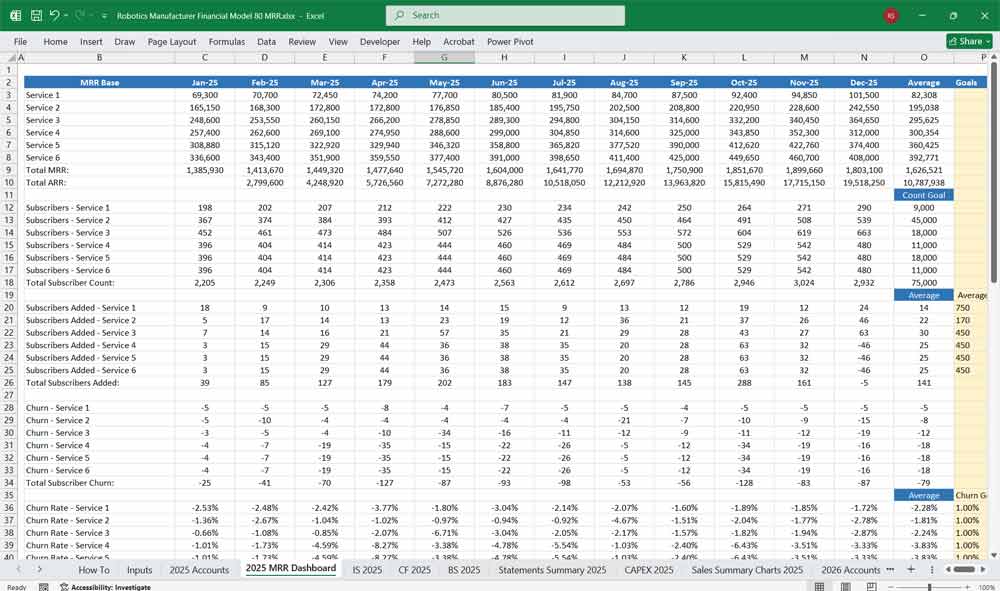

6-tier subscription model for a Robotics manufacturer

This involves structuring offerings that cater to different customer segments, from small businesses to large enterprises. Each tier should provide increasing value, services, and benefits to justify the higher price points.

1. Free Tier Robotics (Basic Remote Monitoring)

Target Audience: Small businesses, individual users, early adopters

Pricing: Free (Limited Features)

Features:

- Remote diagnostics (basic fault detection)

- Limited software updates (security patches only)

- Cloud-based monitoring (real-time status updates)

- Basic user training (1-hour online tutorial)

- Community support (forum access, no direct support)

- Revenue Potential:

- Generates upsell opportunities for higher-tier plans

- Encourages customer onboarding and ecosystem lock-in

2. Starter Tier Robotics ($99/month)

Target Audience: Small manufacturing firms, research institutions, pilot projects

Pricing: $99/month per robot

Features:

- All Free Tier features +

- Preventive maintenance alerts

- Software updates (performance enhancements)

- Remote troubleshooting (AI-guided self-diagnosis)

- 24/7 email support

- Access to a library of automation workflows

Revenue Potential: - Encourages entry-level adoption

- Serves as a gateway to premium tiers

3. Professional Tier Robotics ($299/month)

Target Audience: Medium-sized businesses, logistics firms, warehouses

Pricing: $299/month per robot

Features:

- All Starter Tier features +

- AI-powered predictive maintenance (early failure detection)

- Priority software & firmware updates

- Remote expert diagnostics (human-assisted)

- Workflow automation customization (limited)

- API access for third-party integration

- 24/7 phone & chat support

Revenue Potential: - Strong upsell for businesses that need proactive support

- Encourages long-term commitments

4. Enterprise Tier Robotics ($799/month)

Target Audience: Large-scale manufacturers, high-volume automation users

Pricing: $799/month per robot

Features:

- All Professional Tier features +

- Advanced AI optimization (machine learning-based efficiency improvements)

- Predictive analytics dashboard (real-time performance insights)

- Unlimited workflow automation customization

- Dedicated Account Manager

- On-site support (once per year)

- SLA-backed response time (guaranteed 4-hour resolution)

Revenue Potential: - Provides high-value, mission-critical support for enterprise clients

- Creates strong customer loyalty & retention

5. Industrial+ Tier Robotics ($1,999/month)

Target Audience: Fortune 500 companies, aerospace, automotive, defense

Pricing: $1,999/month per robot

Features:

- All Enterprise Tier features +

- 24/7 on-site emergency support

- Full AI & automation consulting (tailored efficiency improvements)

- Digital twin simulation (real-time process modeling)

- End-to-end cybersecurity protection

- Supply chain optimization AI tools

- Custom R&D collaboration opportunities

Revenue Potential: - Highest-margin tier with long-term enterprise contracts

- Creates opportunities for direct partnerships & R&D revenue

6. Government & Defense Tier Robotics (Custom Pricing)

Target Audience: Military, federal agencies, smart cities

Pricing: Custom (Multi-Million Dollar Contracts)

Features:

- All Industrial+ Tier features +

- On-premises private cloud deployment

- Custom AI & security protocols

- Military-grade encryption & compliance adherence

- Full robotic fleet management tools

- Joint research and innovation projects

- Direct government support & strategic partnership

Revenue Potential: - Provides highly secure, specialized solutions

- Ensures multi-year contracts & defense funding

- Additional Considerations Across Tiers

Scalability:

Each tier is designed to be scalable, allowing customers to upgrade as their production needs grow.Integration & API Access:

Higher tiers offer greater levels of system integration, enabling seamless connectivity with in-house systems and real-time tracking.Flexibility:

Options for rollover of unused print credits and flexible overage billing ensure that customers only pay for what they need.Value-Added Services:

Complimentary design consultations, technical support, and training workshops become more prominent in the higher tiers, adding strategic value beyond just production capacity.Service Level Agreements (SLAs):

Defined SLAs across tiers provide transparency regarding turnaround times, quality standards, and uptime guarantees, with the most rigorous SLAs reserved for Enterprise and Premium tiers.

Final Notes on the Financial Model

Financial model for a Robotics manufacturer

- Scenario Analysis: Create best-case, base-case, and worst-case projections.

- Break-even Analysis: Determine sales volume required to cover fixed & variable costs.

- Sensitivity Analysis: Assess how changes in raw material costs, pricing, or demand impact profitability.

This structured finance model helps a Robotics manufacturing business address a broad market spectrum, offering the right balance between cost, production capacity, support, and customization at each subscription level.

Download Link On Next Page